Ball screw performance continues to improve, thanks to advancements in manufacturing methods and materials. Newer generations of ball screws have higher load capacities, which means they’re increasingly being used for applications with higher loads as well as more challenging environmental conditions. Hence, the rise in ball-screw-driven actuators replacing traditional fluid power actuation methods in some high-force applications.

Newer ball screw designs can also better resist harsh conditions such as extreme temperatures, high particulate levels, exposure to chemicals and high-pressure washdown environments, as well as shock and vibration.

With a growing number of product options, engineers are looking for new tools and services to help simplify the ball screw selection process. Manufacturers are responding with product sizing and selection tools as well as services for custom designs.

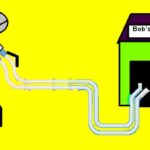

These illustrations show the difference between two types of ball return circuit. The end cap return (pictured above with black end cap) shows a single circuit with multiple returns. This design is best for long lead applications where the lead is greater than 50% of the screw diameter. It offers reduced wear via a patented fingerless pickup design that eliminates the common end-cap wear point and allows for refurbishing.

For example, some screw manufacturers are seeing more demand for custom screw designs for applications that can’t be accommodated by standard off-the-shelf products. As it stands, the ball screw market largely consists of high-volume, standard catalog products, which are suitable for most OEM applications.

The other design, the internal button return, shows a single turn with multiple circuits. Such a design is good for typical lead and diameter combinations.

Case in point; the experience of ball screw manufacturer Dynatect. For starters, they see quite a bit of design diversity in the ball screws they manufacture. In terms of value-added services, they provide engineering support for both OEM and end-user customers.

So instead of a catalog inventory, Dynatect LSI manufactures customized ball screws including extra long length and large diameter designs. (Diameters can range from 5/8 in. to 6 in. with lengths to 65 ft and more.) These custom ball screws are used in manufacturing, material handling, and any application requiring a force multiplier.

Precision ground ball screws from Dynatect offer lead accuracy of +/- 0.0005 in. with lead times of 2 weeks.

“End users and custom machine builders have leveraged Dynatect’s experience developing energy efficient solutions to meet specific thrust load, backlash and position accuracy,” notes Chris Coughlin, National Sales Manager with Dynatect LSI. In fact, selecting the right options can reduce precision ball screw costs by 20% for a typical fleet of machine tools. “By offering both repair, rebuild, and replacement options, the typical machine tool user can save 20% on precision ball screws,” adds Coughlin. (Typically 40% of precision ball screws qualify for refurbishment rather than replacement.)

What’s more, the right design, combined with repair options, can add up to significant savings for a fleet of machine tools. Specifically, when it comes to older designs with external ball return tubes, companies like Dynatact can replace these with an internal return with several advantages including size, interference, breakability, and repairability.

Convergence of ball screw standards — much like that for gearing to metric

Much like the convergence of ISO, DIN and Japanese JIS standards in the area of screw-based linear motion, so too are U.S. gear suppliers seeing consolidation of standards — in the case of gears, to metric-based references. That’s according to Lance Brown, mechanical engineer III at CGI Motion.

We asked him to elaborate on this topic, and here’s what Brown had to say.

CGI Motion is a member of the American Gear Manufacturers Association (AGMA) and participates in a handful of AGMA technical committees. These include the Fine Pitch Gearing Committee, the Bevel Gear Committee, and the Gear Rating Committee. We supply gearing and do work to many standards, and we’re even involved in helping to develop their rules. Currently we’re reaffirming the AGMA’s fine-pitch gear proportion standards.

We recognize the leadership of AGMA president Matthew E. Croson, who has shepherded the introduction of many new technologies into the AGMA. Some are emerging technologies such as cast carbon fiber and others include additive machining, which we haven’t seen in the gear industry before — even though it’s used elsewhere. In fact, there’s now significant focus on emerging gear technologies as well as automation at the AGMA.

Another trend we see is a dramatic increase in the use of metric units instead of English units. In many technical conversations, more design engineers have begun employing metric terminology for specifying gears as well. For example, an engineer might call and ask, “Can you do this metric-sized module or that metric-sized module” instead of asking for an AGMA 12 or AGMA 6. In response, the AGMA is converting a lot of their standards over to metric.

Those of us engineers who are a bit older and still think in inches must convert these units in our heads.

You may also like:

Filed Under: Ballscrews • leadscrews, Linear Motion Tips