In a recent video shoot with our esteemed colleague Paul Heney, I got the chance to experiment with miniature square-rail linear positioners from the mSR actuator series.

In a recent video shoot with our esteemed colleague Paul Heney, I got the chance to experiment with miniature square-rail linear positioners from the mSR actuator series.

Designed and manufactured by the Electromechanical & Drives Division of Parker Hannifin, this series of guided linear-motor driven positioners is engineered to deliver modularity and performance in a compact package.

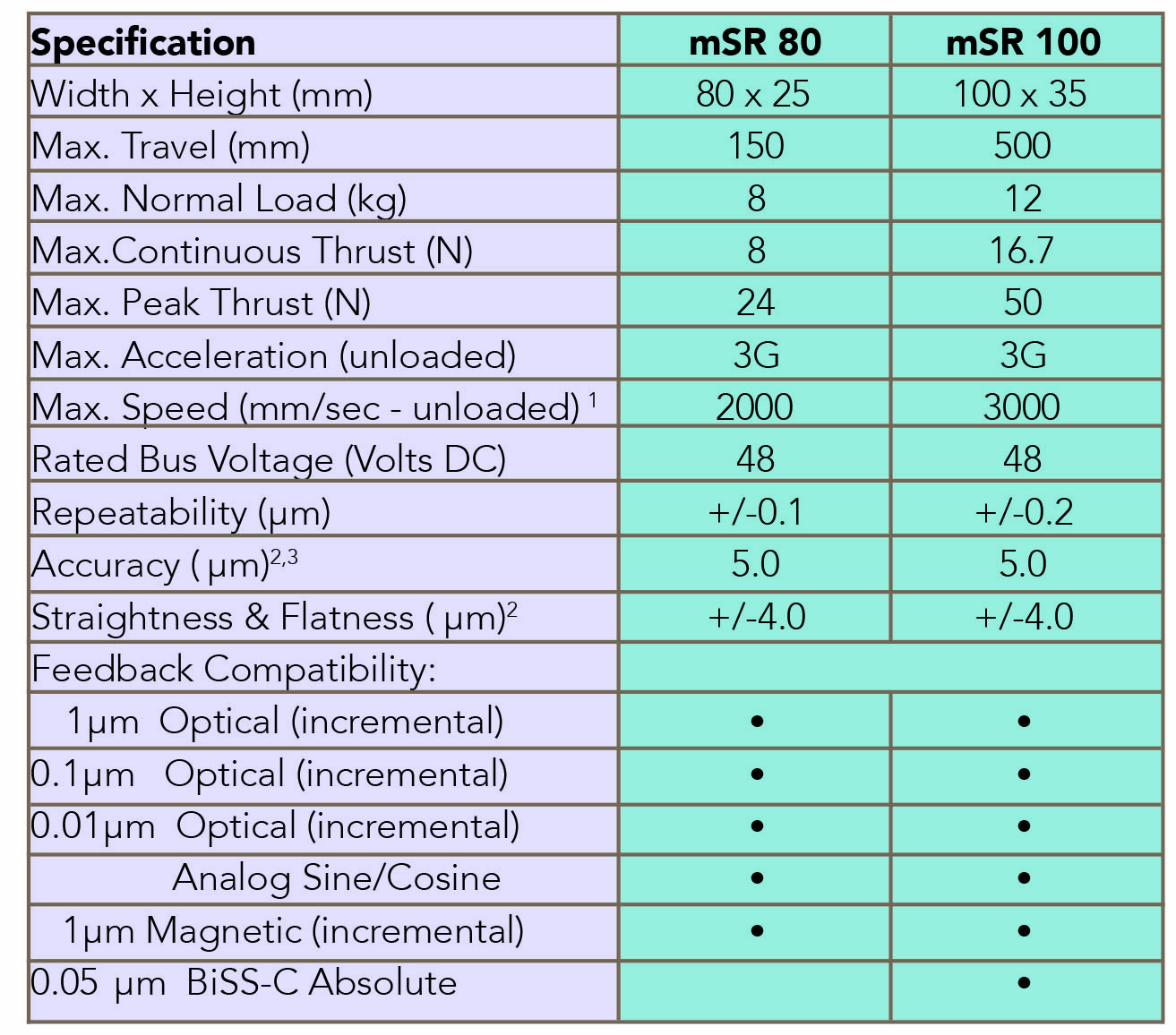

For precision instrument builders who need smooth motion in a small package, the mSR is a linear positioner that provides sub-micron precision in two different form factors … the mSR 80 and the mSR 100.

Dual square rails reliably support the payload.

The mSR 80 measures 80 by 25 mm and delivers travel lengths from 25 to 150 mm.

The mSR 100 measures 100 mm wide by 35 mm in height and delivers strokes from from 25 to 500 mm.

Both mSR units get position repeatability to ±0.01 μm. There are six linear encoder options — Incremental optical, incremental magnetic, analog sine/cosine, and BISS-C absolute. These positioners are suitable for variety of applications ranging from imaging systems in digital pathology equipment, to metrology instruments in semiconductor or electronics manufacturing.

There are also two linear-motor technologies used in this series. The mSR 80 is fitted with a miniature ironcore linear motor and the mSR100 comes with an new ironless linear motor — the ML-18. Both of these motors have been optimized to run between 24 and 48 volts dc.

Given the combination of its geometric performance and miniature packaging, the mSR series positioner is suitable for semiconductor handling and metrology applications. Regardless of whether the application is examining features on the micro or nanoscale – the mSR can be adapted to meet the need with its wide array of encoder options.

The mSR uses tightly integrated home and limit sensors on board the encoder, limiting its cable count to just two.

An optional counterbalance can fit to the mSR 80 providing a robust alternative to pneumatic or spring equivalents so that it maximizes the instruments performance. Plus this mSR positioner offers instrument builders optimized packaging of the linear motor, guidance, encoder, and limit and home sensors in a complete solution …

… so it maximizes instrument performance and works in Z-axis applications such as auto-focusing, for example.

The line of actuators and stages also adheres to instrument regulations and certification, and is both CE and RoHS compliant.

The mSR offers instrument builders a plethora of different encoding technologies and resolutions from which to pick. Standard incremental optical resolutions range from one micron all the way down to 10 nm. An analog sine-cosine option helps motion designs get high resolution when paired controls using interpolating technology. A one-micron magnetic option works for cost-sensitive applications requiring more basic positioning.

Still another option for the mSR is a BiSS-C absolute encoder to give absolute feedback for applications requiring constant positional information.

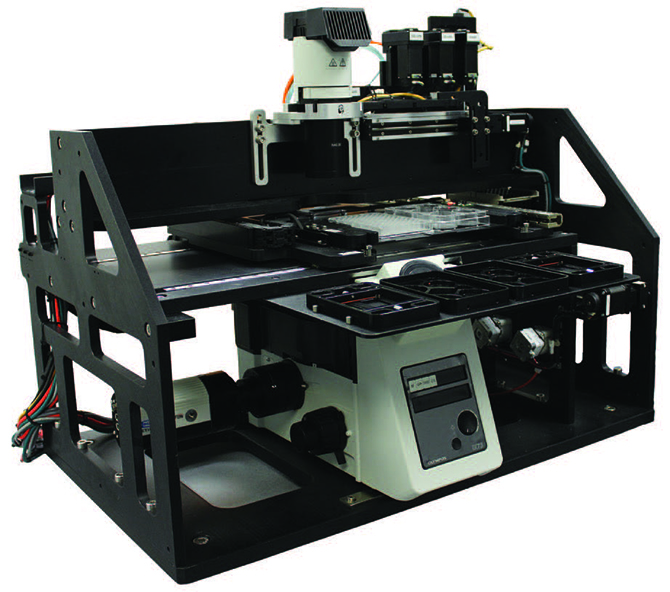

Consider one use: Digital-pathology applications need high precision performance and quick settling times — which makes the mSR a suitable choice here. In fact, emerging cellular therapeutics for regenerative medicine already make use of the mSR for its high precision during picking and placing of cells for cell therapy instruments. These instruments require highly repeatable positioning to pick cells of interest and incubate them for cell-based therapies and other tissue growth.

Consider one use: Digital-pathology applications need high precision performance and quick settling times — which makes the mSR a suitable choice here. In fact, emerging cellular therapeutics for regenerative medicine already make use of the mSR for its high precision during picking and placing of cells for cell therapy instruments. These instruments require highly repeatable positioning to pick cells of interest and incubate them for cell-based therapies and other tissue growth.

For more information on this Parker product, visit the mSR positioner deep link at parkermotion.com.

Filed Under: Encoders • linear, Linear Motion Tips

Tell Us What You Think!