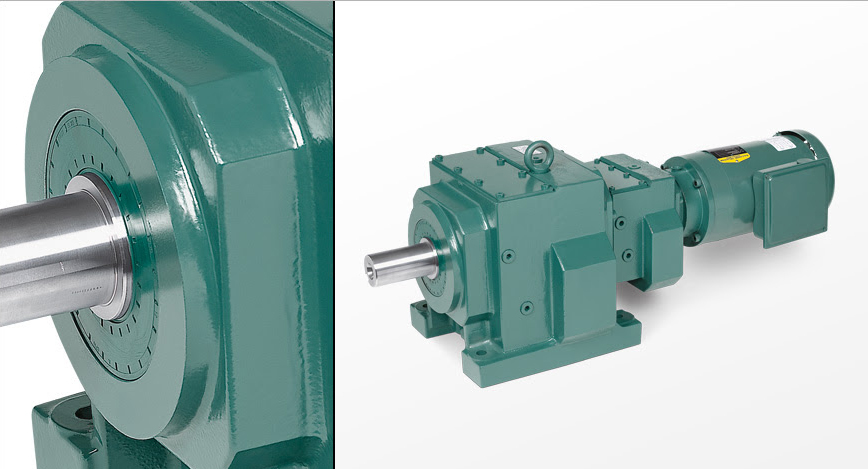

The Baldor Dodge Quantis product family — a full line of modular gearmotors and gear drives — has expanded to offer four and five stages of gear reduction for all three types of gear arrangements; in-line helical (ILH), offset parallel (MSM) and right angle helical bevel (RHB).

Quantis reducers and gearmotors can now be configured in ratios over 7,500:1 with an output torque range up to 14,000 Nm, making the new output speed range 20-times greater than before.

Quantis reducers feature up to 98% efficient gearing and are available with integrated or flange mounted IE3 or NEMA Premium Efficient motors for an energy-saving package. With an advanced design concept, users have the flexibility to configure the product for a wide variety of installations. Whether the application requires the compactness of an integral gearmotor, the durability of a 3-piece coupling, or a separate shaft input for direct-coupled equipment, Dodge Quantis offers thousands of reducer configurations and bolt-on accessories to meet any need.

Quantis gears are manufactured for long-lasting reliability with wear-free designs that are finish-ground with an ellipsoid tooth form. Standard units feature class 30 gray iron gearcase housings, and all units are available with a two-piece harsh-duty output sealing system that provide industry-leading protection against contamination. E-Z Kleen corrostion-resistant, and Ultra Kleen all-stainless-steel units are available for the food and beverage industry.

There are clamp-style or three-piece inputs for easy motor installation and removal. For shaft-mounted applications, RHB and MSM styles feature the patented twin-tapered bushing system that makes it simple to install and remove the reducer from the driven shaft with no damage.

Filed Under: Factory automation, MORE INDUSTRIES, Motion control • motor controls, Motors (gearmotors)

Tell Us What You Think!