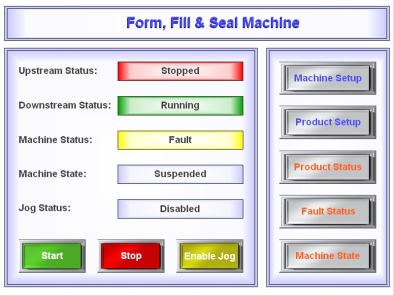

Charlottesville, VA– GE Fanuc Intelligent Platforms, a unit of GE Enterprise Solutions releases its new OEM Solutions Pack for Proficy‚® iFIX 5.0. The new offering is a compilation of pre-configured out-of-the-box graphic objects and screens specifically tailored to machine level HMI/SCADA applications. The components, along with an integrated workspace toolbar and screen templates, accelerate iFIX application development and make it easy to duplicate across many devices and/or machines for ease of integration, consistency of operation, and implementation of data standards, like OMAC.

Menu driven configuration development enables rapid configuration of pre-developed screens for OEMs. Specific tools, dynamos, machine and line-level pre-developed screens, including OMAC templates, will provide consistency across machines, enabling reduced engineering time, faster training and an easier learning curve. Developers can take advantage of the out-of-the-box components as a starting point or customize them to solve a specific problem while maintaining the ease of use for the operators. The trending components and pre-built screens are specifically designed for touch screen operation and enable quick troubleshooting and in-depth visualization of machine data on the plant floor, and with web-client capability in any environment.

The OEM Solutions Pack includes a variety of machine performance screen templates and dynamos tailored to provide easy to use and understand metrics that will support Lean and Six Sigma initiatives. This functionality, along with the base HMI/SCADA control screens, will quickly and easily provide machine level monitoring at a very low cost to the end customer. OEMs can streamline project schedules, enable easy maintenance and deliver repeatable professional-looking systems.

Proficy iFIX offers a robust SCADA engine, rich set of connectivity options, open architecture and highly scalable and distributed networking model. Used in a variety of applications across diverse industries, it is ideally suited for applications as simple as typical HMI applications such as manual data entry and validation to very complex SCADA applications like batching, filtration and distributed alarm management. It also complies with industry standards-making it ideal as part of more IT-focused real time data management system.

GE Fanuc

www.gefanuc.com/oempack

::Design World::

Filed Under: Data acquisition + DAQ modules, ENGINEERING SOFTWARE

Tell Us What You Think!