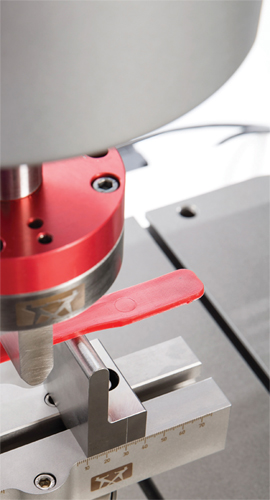

The Instron E3000 uses a T-slot table for regular and irregular grips and specimins

ElectroPuls is driven by a linear synchronous motor and requires additional velocity feedback due to the challenges of driving linear motors with lower inherent damping than traditional rotary designs. While suitable for position control, an LVDT suffers from relatively poor signal stability, and therefore, cannot produce accurate velocity measurements. LVDTs are also susceptible to magnetic fields produced within a linear motor and exhibit increasing non-linearity over longer axes.

Optical encoders, on the other hand, have better signal stability and higher accuracy, making them better in this application. The Instron design team determined that an absolute optical encoder, capable of providing absolute position information without homing, would be the best solution for their bi-axial systems. The encoder offers several advantages over servo mechanisms that use optical linear incremental encoders in conjunction with an LVDT.

The engineering team needed an absolute optical encoder that was compatible with BiSS serial communications, easy to set-up and install, and non-contacting to eliminate the friction and wear that leads to mechanical hysteresis errors. They chose Renishaw‘s RESOLUTE, which offers linear resolutions of 1 nm and speeds beyond 20 m/sec.

“We previously used an LVDT to supply the absolute position feedback needed to commutate a linear motor, and an incremental optical encoder to provide the required measurement and control accuracy,” said Graham Mead, principal mechanical engineer for Instron ElectroPuls. The absolute linear encoder gave the design team functionality and accuracy from one device.

Instron’s E3000 has a twin column configuration with the actuator in the upper crosshead and is electrically powered from a single-phase main supply.

The behavior of dynamic materials-testing machines must be precisely controlled with either strain feedback from an encoder or stress feedback from a load cell. Standards body ASTM International tolerates a deviation of up to 2% of the maximum applied load before a test becomes invalid. RESOLUTE’s high accuracy and excellent dynamic performance permit more detailed analysis of samples at failure, contributing to the accuracy of drawn conclusions.

Renishaw

www.renishaw.com

Filed Under: Actuators, Encoders • linear, Encoders • optical, MOTION CONTROL

Tell Us What You Think!