In this article, we’ll equip you with a better understanding of the key elements of rubber component design and manufacturing — from material selection and design to prototyping and production mold technology.

Optimizing the development of your custom rubber seal can be challenging. Relying on industry specialists and considering potential manufacturing methods and production volumes will enable you to navigate the innovation process. Custom rubber seal manufacturing experts offer a great understanding of how production volumes, methods, materials, and design interrelate and impact costs as well as affect performance and time to market. They also contribute diverse skillsets.

One powerful skillset is the capability to effectively prototype production-intent custom elastomer components. Prototyping is advantageous, as it allows testing on the live part before committing significant budget and resources to any aspect of component design, giving you the opportunity to adjust and consider the potential production outcomes. By bringing the prototype design, materials, and methods as close to the production equivalent as possible, you will yield accurate component performance results and the highest quality production.

Take Advantage of Engineering Expertise Early

The earlier you involve your custom rubber manufacturer in your product development process, the better. Relying on elastomer manufacturing specialists can help you prevent design and performance issues while achieving budgetary constraints.

Your rubber component is the final piece of the product design puzzle, and it must fit your product — there is no room for deviation. Failure to recognize the importance of the rubber component design can negatively impact your costs and product performance.

In short, the earlier you talk to your rubber component manufacturing specialist about your project and objectives, the easier you will arrive at the best process and material solution.

Getting Started: Questions To Ask Yourself

• What will the component’s function be?

• In what environment will it function?

• Does the component need to be multi-functional?

• How long must it perform correctly?

• What characteristics must the component exhibit?

When it comes to manufacturing custom elastomer components, there are three common molding techniques:

Injection molding

Injection molding injects heated elastomer material into the mold under high pressure. The compound flows from the heating chamber to a series of runners and sprues, which direct the rubber into the tool at multiple points. Some materials are better suited for injection molding than others. Elastomers with better flow rates will move through the machine more favorably than highly viscous materials. Injection molding is ideal for high-volume production and can yield better results for components with generally lower geometric complexities. Injection molding is typically an automated process, making operator costs null.

Transfer molding

Transfer molding is most like injection molding. A sheet of rubber material is placed into a pot, located above the top plate, that features gates through which the compound flows into the mold below. Above the pot, a plunger lowers and compresses the material and, while also applying heat and pressure, forces the compound to flow through the top plate gates and fill the entire mold cavity.

During this process, the compound fills the contours of the pot and forms a pad of elastomer that doesn’t fill the mold. This pad is disposed of as waste, making transfer molding ideal for lower-cost materials.

Compression molding

Compression molding is suitable for low-volume production. A pre-form of rubber compound is placed into one side of the tool cavity. One half of the tool is closed against the other, and heat and pressure are applied to enable the material to flow and fill the cavity.

Compression molding is ideal for more malleable materials, with medium-hard elastomers working best. This method is often better suited for simple designs, as the pre-form compound is initially very flexible and can be difficult to insert into complex molds. Additionally, compression molding can have a very high cavity count, which helps to offset labor costs.

Unlike injection molding, compression molding machines require an operator, making the process subject to labor availability and more human error. Applications for compression molded components range from simple O-rings to complex diaphragms with diameters exceeding 10 inches (254 millimeters).

How To Choose the Right Tool for the Job

Tooling, or the mold that forms the elastomer, typically consists of two or more custom-machined cavities and steel plates. In most elastomer molding processes the tooling plates undergo heat and pressure to force the rubber compound into the tool. It’s important for all parts of the mold to have consistent dimensions, close tolerances, and proper surface finishes to ensure high-quality finished components.

Tool construction begins with CNC machines hollowing out a solid steel block that is divided into multiple plates, according to the component’s design. If a design requires interior contours, a steel core pin is inserted into the tool to shape the internal features of the finished component.

Complex designs require equally complex tooling, driving up the overall cost of the finished component. Some manufacturers opt to cut this cost by using cheaper tooling. This choice, however, can erode the finished product’s mechanical properties. For these reasons, high-quality tooling pays for itself by ensuring end-application performance reliability.

In addition, the tool cavity count and size are influenced by factors like component size, complexity, production volumes, molding press size, and tonnage, as well as component function and material type.

Consider Your Production Volumes

Production volume impacts molding machine selection and cost-effectiveness and is typically

the first factor to consider when deciding which molding process to use. For example, at high production volumes, some manufacturing methods cannot keep up with the cycle times necessary, ultimately affecting the end-product’s time to market.

The industry rule of thumb is to use injection molding when producing a million components or more per year, while low-to-medium volume production is the sweet spot for compression and transfer molding.

Finding the Right Material

To decide which rubber compounds to use, it’s critical to understand the function of the finished component. For example, if the objective is to seal a fluid, you should know whether it needs to seal against many different fluids or one specific fluid.

Some common factors to consider include:

• Providing structural support.

• Energy transmission or absorption.

• Pressure and temperature conditions.

• Wet or dry environments.

• Exposure to constant or cyclical pressures.

• Exposure to dynamic or static stresses.

Failure to consider the critical requirements and functions may result in failures.

Trelleborg Sealing Solutions has an extensive compound portfolio, and we commonly formulate new materials to meet application-specific requirements for custom-tailored components.

Important Material Qualities:

• Shrink rate.

• Flow rate.

• Rubber process analysis (RPA).

• Compression set.

• Corrosion resistance.

• Swelling.

• Abrasion resistance.

• Biocompatibility.

Design Features That Influence Product Development

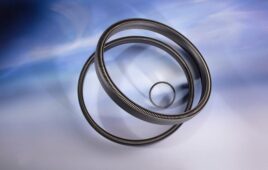

Molded rubber components vary in design complexity and can range from simple ring seals to complex subcomponents that must be overmolded together. The design will naturally push you toward different materials or processes to facilitate the optimum manufacturing method. Here are some of the most common design features that will have an impact on your choice:

Corners — Sharp corners are generally difficult to manufacture and increase the likelihood of component defects. Although costly, high-quality tooling can mitigate potential defects and impact the success of the end-product.

Undercuts — An undercut is a feature that projects back into the main body of a component. The closer an undercut comes to the axial center, the deeper the undercut. Deep undercuts provide their own set of challenges, as they make the component difficult to remove from the mold. Orientation also contributes to removal difficulties. For example, if a deep cut is perpendicular to the mold opening, it can be impossible to remove the component from the mold.

Undercuts — An undercut is a feature that projects back into the main body of a component. The closer an undercut comes to the axial center, the deeper the undercut. Deep undercuts provide their own set of challenges, as they make the component difficult to remove from the mold. Orientation also contributes to removal difficulties. For example, if a deep cut is perpendicular to the mold opening, it can be impossible to remove the component from the mold.

Holes

If your rubber component requires holes, a pin must be placed inside the mold cavity. This core pin is responsible for forming the internal contours of the finished component. The molding process uses high pressures with the potential to deflect the core pin and produce a hole with inconsistent dimensions. Designing core pins with diameters as large as possible, particularly at the pin base, will minimize the risk that the pin will bend or break during the molding procedure.

Other guidelines to keep in mind:

• The hole height should not be more than twice the diameter.

• The minimum hole diameter should be 0.050-in. (1.27 millimeters).

Sharp edges — Components with thin edges, often referred to as “knife edges” or “feather edges,” usually tear as they are removed from the mold. Post-cure deflashing steps can further chip the edge, creating additional imperfections. If possible, it’s best to avoid incorporating knife edges in designs unless absolutely necessary. If your component does require a thin edge, squaring off the edge with a flat minimum of 0.010-in. (0.254 millimeter) will significantly reduce the likelihood of damage.

Overmolding — Sometimes elastomer components must be paired with subcomponents of other materials like steel, brass, aluminum, or plastic. Typically, the rubber compound is overmolded over the non-rubber subcomponent. When designing rubber over-molded components, there are a few design principles to keep in mind to maximize the strength of the bond between the elastomer and insert.

• Cover as much of the insert’s surface as possible with rubber, maintaining a minimum thickness of 0.020-in. (0.51 millimeter).

• Avoid shutting off the flow while the compound travels along a vertical surface.

• Provide proper lands (steps).

There are two types of bonding methods used when overmolding rubber to a subcomponent material:

• Mechanical bonds require the insert to feature holes, projections, or depressions on its surface. For chemical bonding to occur, special adhesives must be applied to the insert before molding. This type of bond will keep an overmolded component as one single object without relying on a component or insert shape. Components used in demanding applications usually employ a combination of both mechanical and chemical bonding.

Incorporating inserts into component designs usually necessitates secondary pre- and post-mold tasks, such as insert surface etching, masking, unmasking, applying adhesive, and deflashing.

Flash — The excess rubber that escapes in small amounts from the mold while undergoing heating and pressure is called flash. Usually, this small amount of rubber is forced through the parting lines, or seams, between the tooling plates. It is common to remove flash as part of the post-molding process via manual tear trimming, cryogenic processing, tumbling or precision grinding.

Gates — Transfer and injection molded components usually employ gates to ensure the compound uniformly flows into the tool. You can place gates at various locations on the cavity. Gate marks, which are the small, raised spots or depressions where the gate interacts with the cavity, are left behind after the molding process is complete and can sometimes impact seal functionality and appearance. For these reasons, it’s important to find a balance between gate size, placement, and number. Since these aspects vary, even among the same tool design, determining these features must be completed on an individual basis for each component. Look to your project goals as guidelines to determine the best gate strategy, and consider factors like material hardness, dimensional tolerances, and cosmetic and customer requirements.

Building Your Prototype

When operations are running at maximum capacity, unforeseen issues can impact uptime significantly, leading to missed deadlines. Prototyping provides opportunities to refine designs and manufacturing processes before production and is essential to ensure full-scale production goes off without a hitch.

During the prototyping phase, especially with complicated designs, it’s best to manufacture and test under conditions as close to the operational manufacturing environment as possible. Doing

so will provide the most accurate results and help forecast the project’s level of success. Prototyping can also inform you about which manufacturing method is best, allowing you to experiment with different materials, design features and production methods.

Meeting project deadlines should never deter you from prototyping. In the end, prototyping saves time, cost and energy. At Trelleborg Sealing Solution, a fully equipped, state-of-the-art Innovation Center provides an engineer-to-engineer experience, along with a fully integrated design-prototype-build-test process, all under one roof. This immersive process accelerates innovation, allowing us to condense weeks of development into days, turning around production-intent prototypes at unparalleled speed.

Conclusion

Examining manufacturing methods and production volumes, in addition to focusing on materials and design, are necessary aspects of elastomer component development. Materials science experts product engineers and tooling engineers at Trelleborg Sealing Solutions have the experience and expertise to help you navigate the complex interplay between all of these aspects. This allows you to control costs, get to market faster, maximize performance and ensure your resources are optimally utilized.

Trelleborg Sealing Solutions can help solve your toughest application challenges with a custom elastomer manufacturing process that meets all your requirements for cost, performance, and target launch date.

Minnesota Rubber & Plastics

www. mnrubber.com

Filed Under: Seals • O rings, Seals