Industrial automation manufacturer and Internet of Things platform developer Opto 22 has announced groov 3.4 — an update to its mobile operator interface system. With this new version of groov, operators can trend a lot more data over a much longer period: up to 5 years. groov’s built in trend gadget now offers an interactive type of trend that handles many more data points.

This updated version of groov lets operators choose between two trend types: classic and interactive.

- Classic is the original trend for a relatively small number of data points, collected over a period of up to 7 days.

- Interactive is the new trend for much more data over longer periods. Operators and technicians can zoom in and out to see specific time periods and data details in two ways: click a preset tab, or use the built-in navigator to move through trended data.

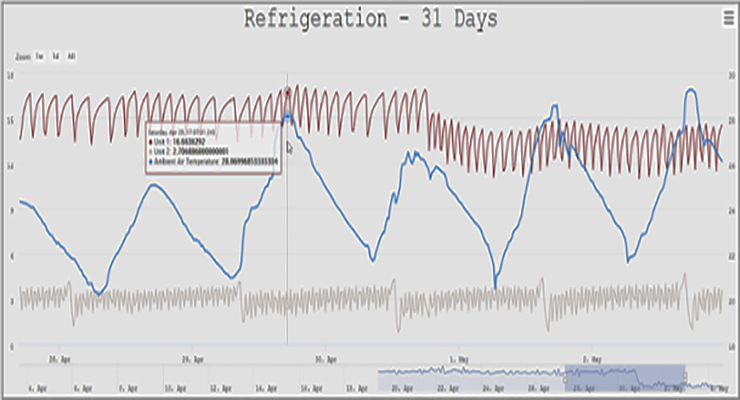

In the trend image above, operators see the preset tabs in the upper left. This trend is for 31 days, and the tabs are preset to show 1 week of data, 1 day, or All (the whole 31 days). The tab presets change based on the overall period of the trend.

In the image, operators also see the navigator at the bottom of the trend. The blue-gray block shows the data period operators are looking at now. Operators can grab the handles on either side of it to see less or more, or tap another spot on the navigator line to see the same amount of data at a different time or on a different date—all from a mobile phone, tablet or browser window on a PC.

In both Classic and Interactive trends, operators can download individual pen data for the entire trend period to log it, just by clicking the button in the upper right of the trend. Note that in an Interactive trend, operators are downloading data for the whole trend period, not just the section in view at the moment. All users except Kiosk users can download data.

Free trial version and online demo: A fully functional version of groov Server for Windows is available to download and try so you can see your own system’s data on a smartphone, tablet, or other mobile device. The groov Free Trial operates for two hours without a license and can be restarted as needed. You can also see groov in action immediately and try it yourself with a live online demo available at groov.com/see- groov-now.

What is the mobile operator interface system groov?

groov is a zero-programming, web-based way to build, deploy, and view effective, scalable industrial IoT and edge computing applications. With groov’s feature set, almost any electrical device can join the industrial Internet of Things and be monitored and controlled through web- based operator interfaces that run on mobile devices and other computer-based systems.

With a native Node-RED development environment, the groov Box is the suitable toolset for IIoT application developers. groov fuses together an industrially rugged hardware platform, data visualization for mobile and web clients, robust industrial automation protocol support including Modbus/TCP and OPC UA, and advanced data flow processing. Add these to its ability to connect multiple data sources including devices, databases, and third-party APIs (application program interfaces), and the groov Box becomes a single, cohesive, cost-effective, and powerful platform for nearly any IIoT or edge computing application.

groov operator interfaces can be viewed on almost any mobile device or computer regardless of its manufacturer, operating system, or screen size, including smartphones, tablets, PCs, and even smart high-definition televisions.

For mobile devices like iPhones, iPads, and Android-based smartphones and tablets, a groov View app for iOS and Android is available free of charge on the iOS App Store and Google Play Store. The groov View app provides a native mobile experience for operator interfaces built with groov. These interfaces can also be viewed in the mobile device’s built-in web browser.

groov can augment existing human-machine interfaces (HMIs) and Supervisory Control and Data Acquisition (SCADA) systems by making important information available to authorized users at any time and in any location. Users can also receive event-based email messages, for example when a connected machine or system needs attention.

groov is available as either the standalone groov Box, an industrially hardened hardware appliance, or the PC-based groov Server for Windows software. In addition to Modbus/TCP networking, groov supports OPC Unified Architecture (OPC UA) to communicate with a variety of machines and systems on the plant floor, including PLCs, DCSs, PACs, databases, and OPC-DA servers. groov also communicates directly with Opto 22 SNAP PAC System controllers.

Pricing and availability for the interface system

groov 3.4 is available now directly from Opto 22 and from Opto 22 distributors worldwide. groov platforms start with either the standalone groov Box hardware appliance (GROOV-AR1- BASE) at a list price of $1295.00 USD or groov Server for Windows software (GROOV-SVR-WIN-BASE) at a list price of $995.00 USD. To communicate with multiple Modbus/TCP devices or SNAP PAC controllers, move up to groov Plus (GROOV-LIC-PLUS) for an additional $695.00 USD. To communicate with OPC UA-compliant systems and equipment as well as with multiple Modbus/ TCP devices and SNAP PAC controllers, move up to groov Enterprise (GROOV-LIC-ENT) for $1595.00 USD over the base price.

Opto 22 designs and manufactures industrial control products and Internet of Things platforms that bridge the gap between information technology (IT) and operations technology (OT). Based on a core design philosophy of leveraging open, standards-based technology, Opto 22 products are deployed worldwide in industrial automation, process control, building automation, industrial refrigeration, remote monitoring, and data acquisition applications. Designed and manufactured in the U.S.A., Opto 22 products have a worldwide reputation for ease-of-use, innovation, quality, and reliability. For over 40 years OEMs, machine builders, automation end-users, and information technology and operations personnel have and continue to trust Opto 22 to deliver high-quality products with superior reliability. For more information, contact Opto 22 at www.opto22.com.

You may also like:

Filed Under: I/O modules, Displays • HMIs • operator interfaces • monitors, MOTION CONTROL

Tell Us What You Think!