Elkton, MD — W. L. Gore & Associates, Inc. has developed a series of new venting products that prevent leakage in liquid fertilizer containers for organic, foliar, gardening and horticultural fertilizers and supplements. GORE™ Packaging Vents protect against product leaks by equalizing pressure, which reduces container distortion caused by altitude, temperature or climate changes.

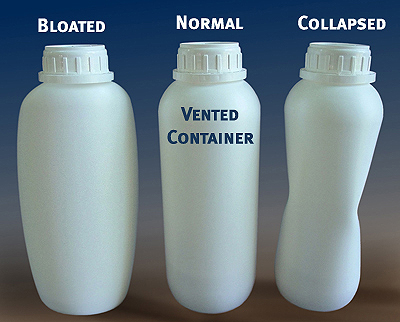

Liquid fertilizer formulations contain active ingredients that can release gases that cause containers to collapse or bloat when combined with altitude and temperature changes during transportation and storage. Bloated containers are at risk for leaks that can result in loss of product and potential sales revenue. In addition, damaged containers can cause harm to a product’s brand image.

GORE™ Packaging Vents protect the container and its contents because the gas-permeable, microporous expanded polytetrafluoroethylene (ePTFE) membrane used in the vents’ construction repels liquid fertilizer formulations while allowing air to pass through freely. These unique vents eliminate the need for increasing headspace in the container or increasing container wall thickness. According to Terry Czerwinski, global product manager for GORE™ Packaging Vents, “Packaging engineers can reduce a container’s weight, which in turn reduces shipping and recycling costs, ultimately affecting the bottom line. By integrating our vents into liquid fertilizer containers, customers have been able to control excess material costs while improving the integrity of their containers and fertilizer products.”

W. L. Gore & Associates has developed a complete line of GORE™ Packaging Vents for dry and liquid fertilizers. These products provide superior performance for sticky, viscous fertilizers that contain high concentrations of particulates in suspension. Gore is the industry leader in engineering membranes and liner solutions that are optimized for their end-use. These vents are readily available in a variety of forms including cap liners, induction liners, molded components and adhesives for easy integration in a wide range of containers.

W. L. GORE & Associates, Inc.

www.gore.com/fertilizers

::Design World::

Filed Under: Materials • advanced, Packaging

Tell Us What You Think!