PEEK (polyetheretherketone) is a high performance thermoplastic. When used as an alternative material, utilizing MR&P’s proprietary processes and designs, these PEEK components provide long operating life with chemical resistance and excellent retention of mechanical properties up to 570°F (300°C). PEEK components are highly resistant to thermal degradation as well as attack by both organic and aqueous environments.

New medical equipment and device designs have increasingly rigorous performance requirements, according to the design experts at MR&P. PEEK is one of many high performance materials utilized by MR&P in its designs for the medical industry.

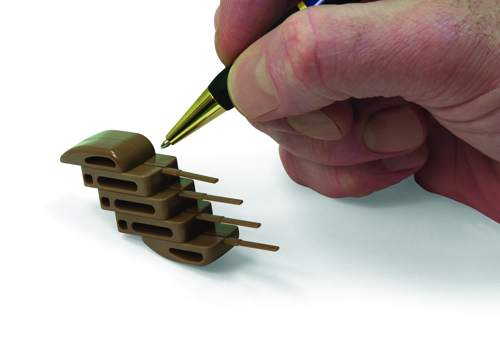

PEEK components from MR&P are ideal for applications in medical appliances, medical pumps, IV systems, feeding devices and both implantable and non-implantable medical devices. PEEK is particularly useful where fluid isolation is required by the seal design.

MR&P is equipped to provide assistance with design and materials engineering from a broad range of medical grade material options. In addition to PEEK, these include compounds compliant with ISO 10993, USP Class VI, and FDA requirements. MR&P operates an ISO 13485:2003 certified quality management system and manufactures medical seals in Class 10,000 and Class 100,000 clean rooms.

In addition to manufacturing components and seals, MR&P’s precision molding capabilities comprise of silicone molding and bonding, processing of high-performance rubber and plastics, rubber-to-plastic conversions, and metal-to-plastic conversions. These capabilities include the manufacture of complete medical device products involving complex assembly through final packaging.

Minnesota Rubber And Plastics

www.mnrubber.com

::Design World::

Filed Under: Medical-device manufacture, Materials • advanced

Tell Us What You Think!