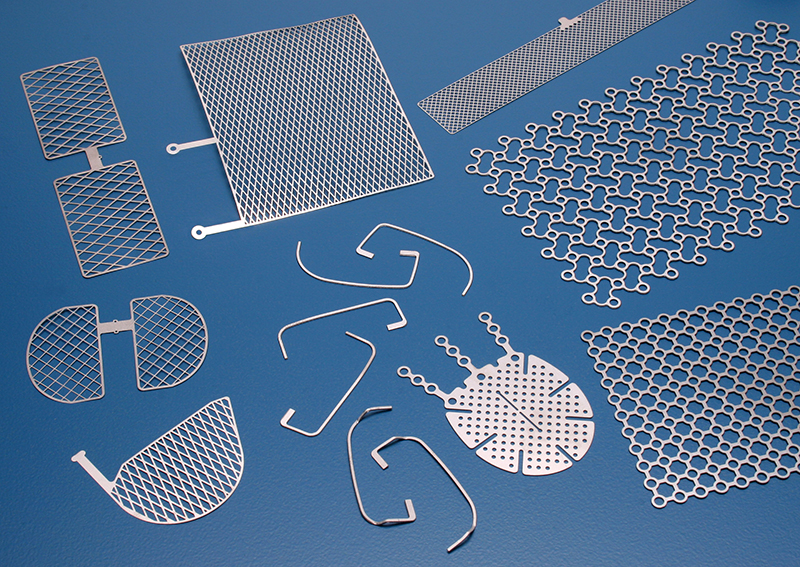

Tech-Etch, which specializes in photo chemical etching, introduced a line of titanium components. Because of its low weight, strength, and corrosion resistance, titanium is used in everything from jet engines to eyeglass frames. Titanium is inert and completely biocompatible, making it useful in many medical implantation applications such as maxillofacial and craniofacial reconstruction plates, as well as anode and cathode battery current collectors and telemetry antennas found in implanted medical devices. Tech-Etch also supplies component parts made from other specialty materials like nitinol, niobium, Elgiloy, tungsten and polyimide to the medical device marketplace.

Key Features

- Parts range in thickness from .0005” and up

- Useful in many medical implantation applications such as maxillofacial and craniofacial reconstruction plates, as well as anode and cathode battery current collectors and telemetry antennas found in implanted medical devices

- Designs can be proved in preproduction quantities without having to commit to expensive tooling

- Laminating, plating, heat treating, and assembly are available in-house

Filed Under: Materials • advanced