All image credit: GE

There are places in the world that make us feel small and force us to marvel at the skills and ambitions of their architects and engineers. They include cathedrals in Europe, NASA’s Cape Canaveral rocket launch pad or the Panama Canal. GE’s gas turbine plant in Greenville, S.C., may not be on everyone’s list. But it comes close.

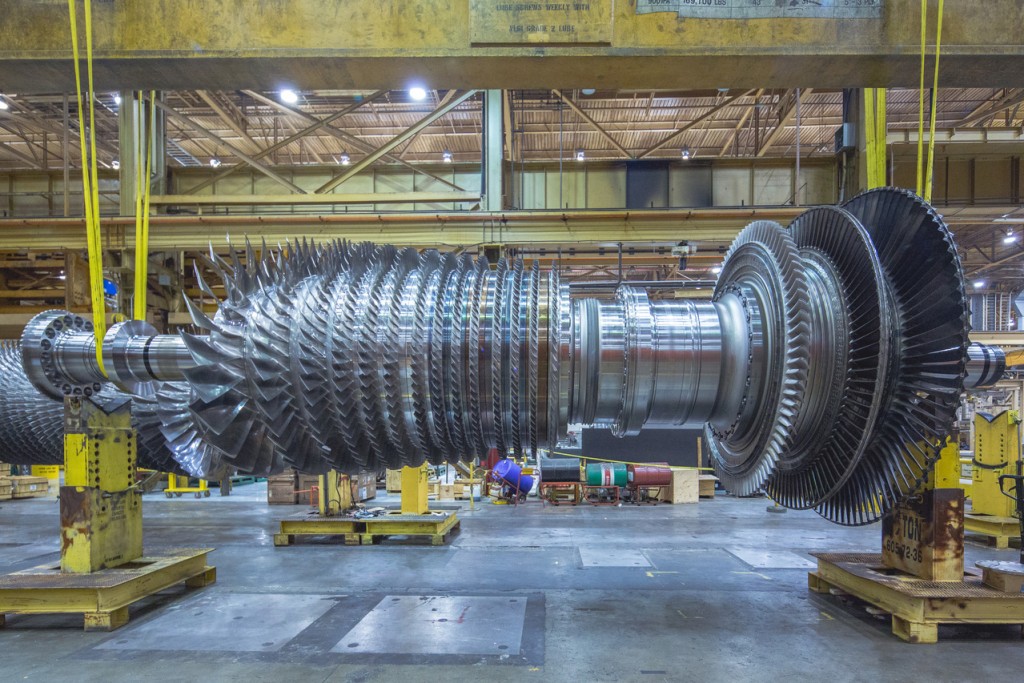

The plant’s several manufacturing halls – equivalent in size to nearly 21 football fields – strike most first-time visitors as the playroom of a giant toddler. Massive yellow gantry cranes lift multi-ton rotors and stators gleaming like alien silver sunflowers. They flip them around their axis, and stack them on shafts the diameter and length of tree trunks.

The above image shows a series compressor rotors on the left and three turbine rotors on the right.

The place smells of high-grade steel and pulses with an industrial symphony of electrical motors cutting in and out. Computer-guided milling machines larger than delivery trucks use jagged cutting heads drenched in white cooling liquid to shape huge turbine wheels.

The plant, which opened in 1968, even has its own railroad spur and also America’s largest train turntable to move the finished turbines around. There’s also a natural gas plant that supplies a unique test stand designed to push turbines to the limit and withstand hot wind jetting out of them at 1,100 mph – 10 times faster than a Category 3 hurricane.

The above image shows a gas turbine on the half-shell with three turbine rotors near the front and compressor rotors in the back.

The place also have a 70,000-square-foot lab replete with 3D printers and powerful lasers. Engineers use them to develop and test parts for next-generation machines like the air-cooled Harriet 9HA turbine – the world’s largest and most efficient gas turbine. Although the facility is strictly off limits to outsiders, GE Reports recently got a tour.

The above image shows two gas turbine shafts suspended in the air with stacked compressor and turbine rotors.

Building gas turbines involves a touch of rocket science and even their production resembles a space factory. Here three GE gas turbines as getting ready for shipping.

Finished gas turbines are getting ready for shipping.

A gas turbine of the half-shell. This image shows silver compressor blades in the front and turbines blades in the back.

The compressor section and inlet casing.

A worker is inspecting the top shell of a gas turbine.

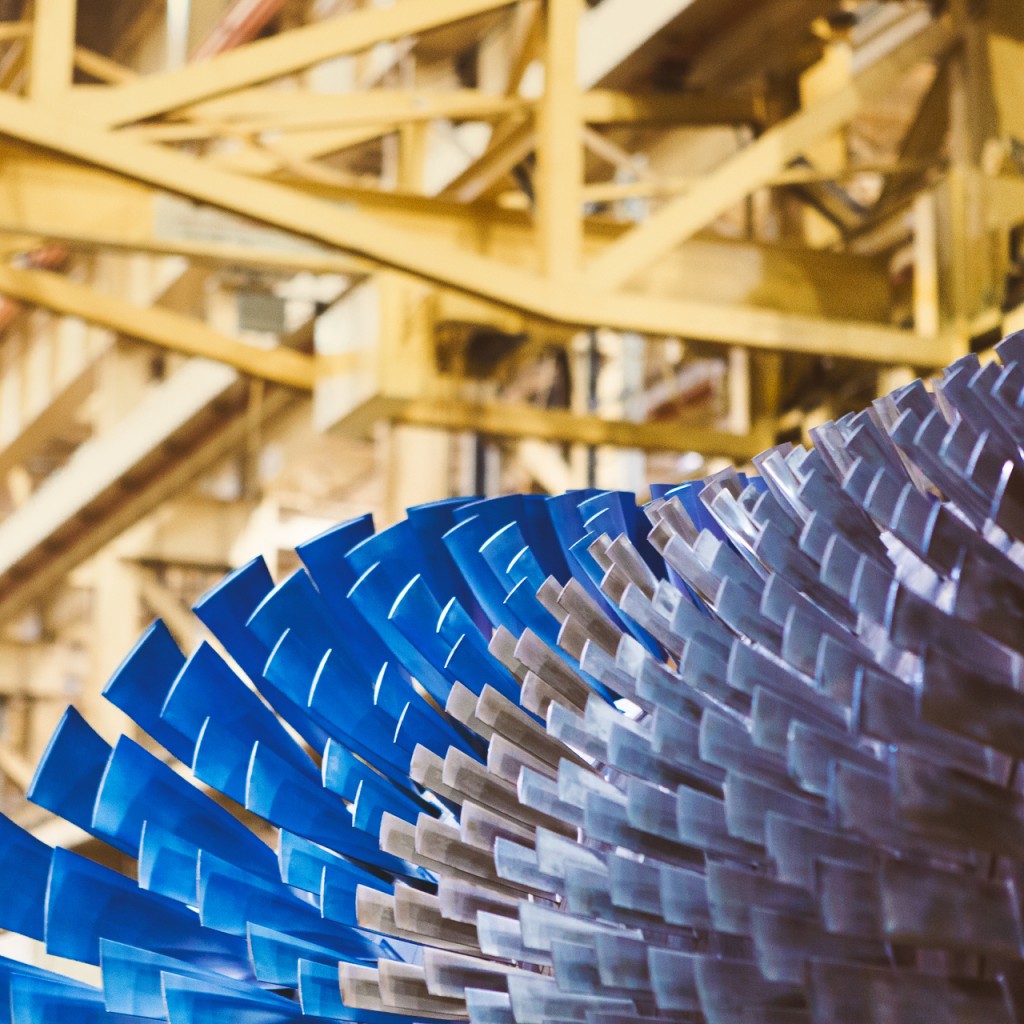

A series of compressor blades. They are highly polished and their blue color is a light reflection.

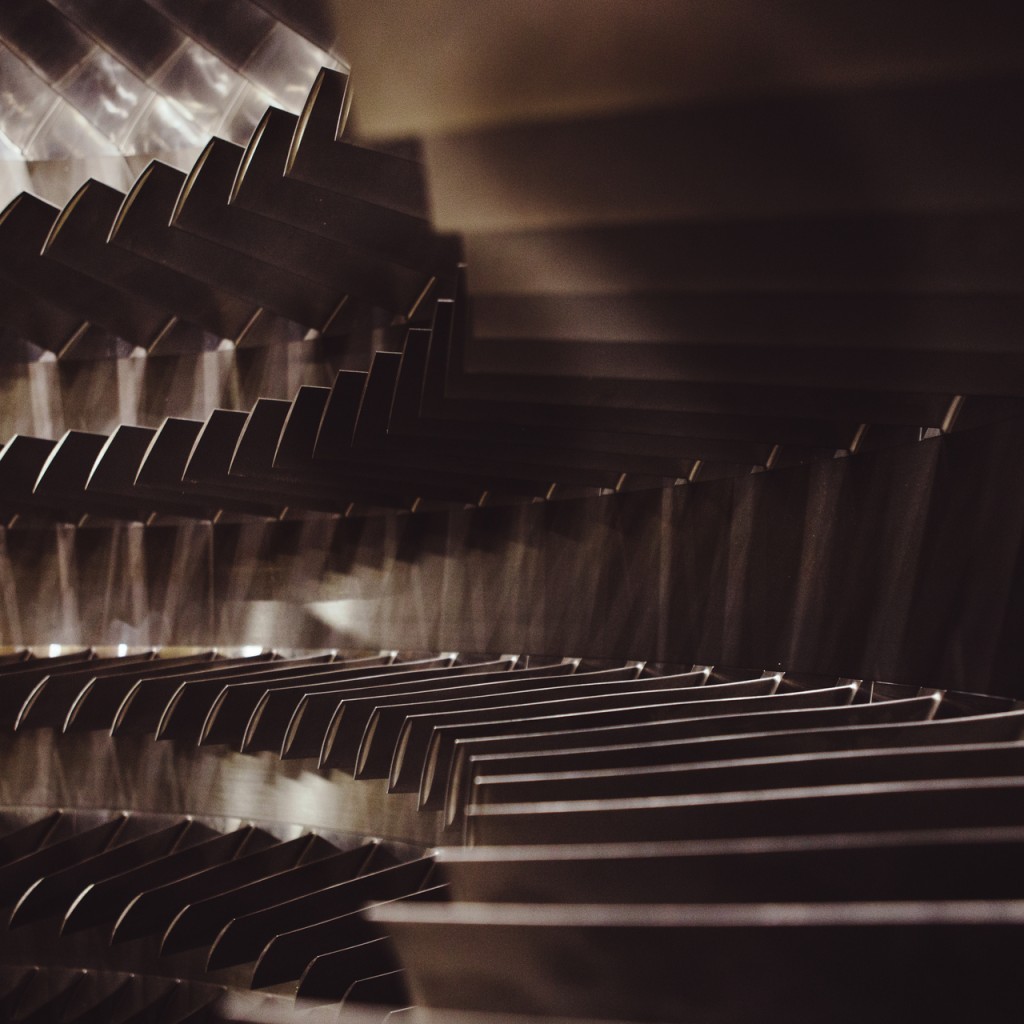

The inside of the compressor with stationary compressor vanes.

A gas turbine casing.

These “dovetail joints” hold blades in place.

A gas turbine stator.

Compressor blades.

A detail of cooling holes in turbine blades.

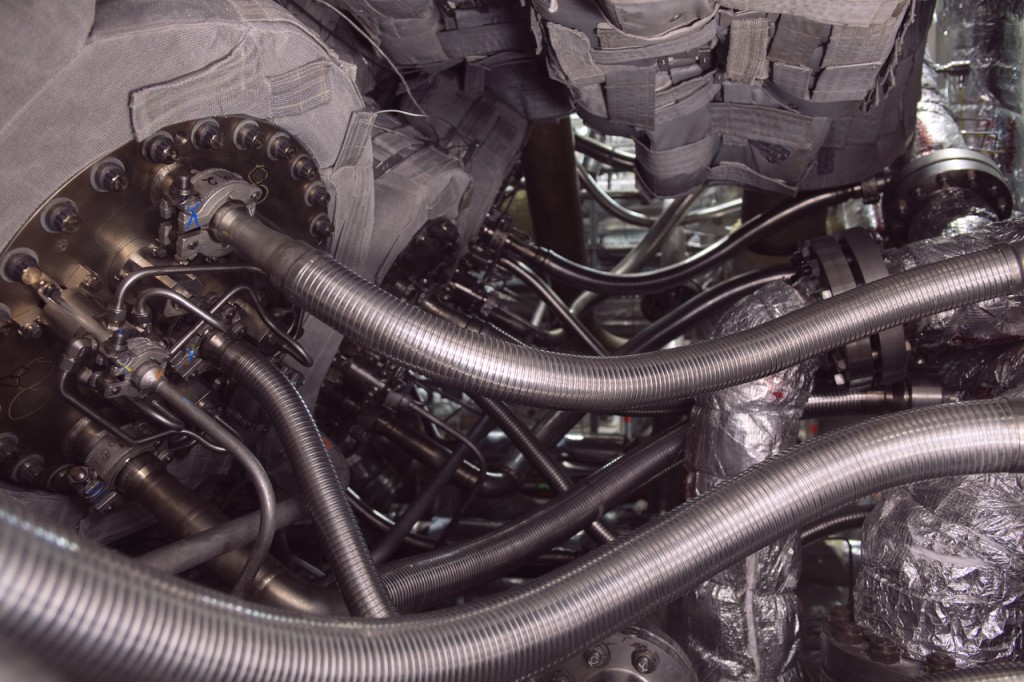

These fuel lines feed one of the test turbine combustors at the testing facility.

These fuel lines feed one of the test turbine combustors at the testing facility.

Exhaust vents at the testing facility. The holes are the size of wine barrels and they must withstand multiples of hurricane-force winds.

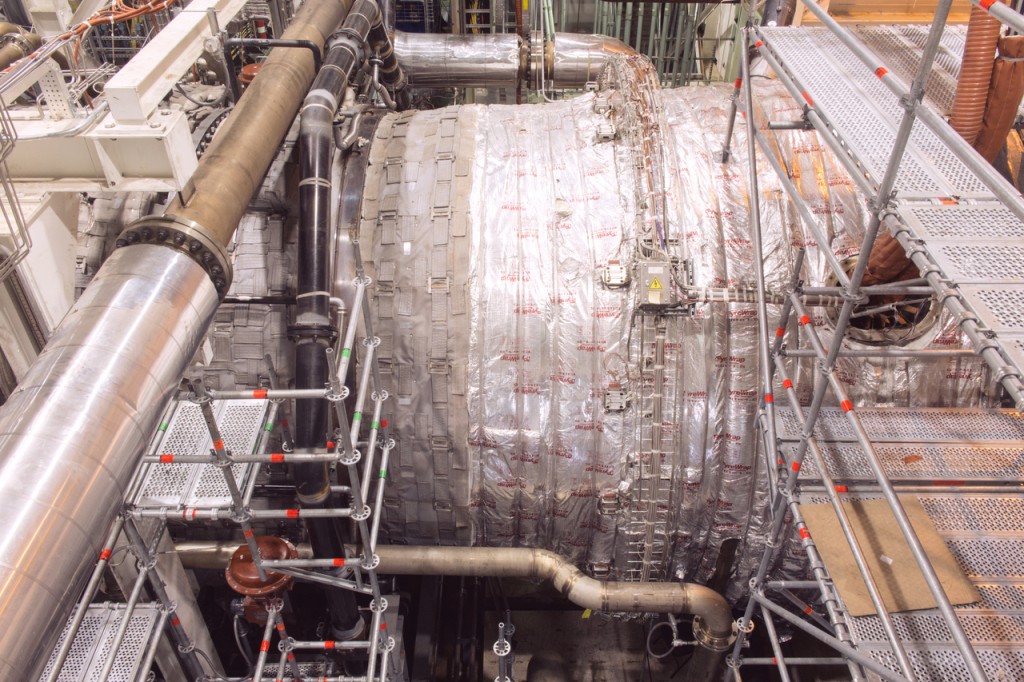

GE’s latest 9HA air cooled turbine is powering through testing. Engineers and using thousands of sensors to gather data and feet to industrial software for analysis.

Filed Under: 3D printing • additive • stereolithography, Industrial automation