Shifting gears in a tractor transmission depends on the integrity of a six-component valve assembly. The check valve is critical to the operation of tractors and other off-road vehicles. It allows pressurization of the transmission to between 1 and 2 psi, ensuring evacuation of oil from specific transmission chambers for shifting gears.

Valve assembly integrity is crucial because components are not easily accessible for service in the transmission. Component failure can inhibit transmission shifting and tractor operation resulting in transmission damage and warranty issues. To meet these challenges, engineers at Minnesota Rubber and Plastics provided an improved design and simplified the assembly process.

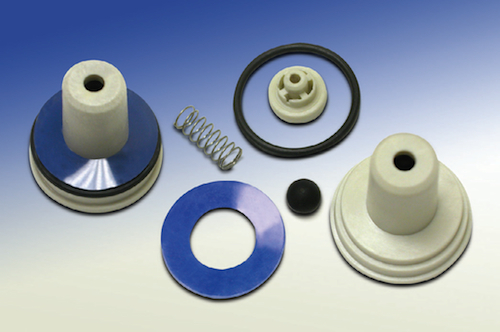

For the transmission’s harsh operating environment, Polyphenylene Sulfide (PPS) was determined as the most suitable plastic material for the valve body. A nitrile (NBR) ground rubber check ball, an NBR O-ring, a coil spring and a PTFE stamped washer were also included in the assembly. The ball and spring were assembled into the body and the retaining spring was welded in place. An outer O-ring and PTFE washer were then assembled on the valve body.

Minnesota Rubber and Plastics

www.mnrubber.com

::Design World::

Filed Under: Valves, Materials • advanced, Off highway • construction • agriculture

Tell Us What You Think!