Engineers at Johns Hopkins University are investigating the use of a robot (MrBot) that can operate within the closed bore of magnetic-resonance imaging (MRI) equipment to help physicians perform remote biopsies of tumors under MRI guidance. Researchers involved in the project say that MRI is ideal for this type of application because it is the preferred method for imaging soft tissue, and it provides an image that lets the physician manipulate the robot so that a needle can be inserted precisely in the center of a tumor.

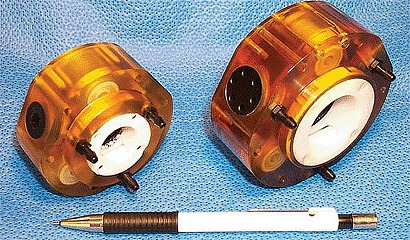

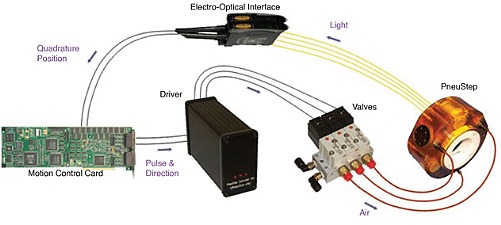

However, such a system has yet to hit the market because electromagnetic motors typically used in robotics are incompatible with MRI. Ultrasonic (piezoelectric) motors are magnetism free, but they present conductive components and use electricity, which creates image distortions if operated within a certain distance of the object. Engineers at Johns Hopkins have developed a pneumatic step motor to overcome these challenges. PneuStep is the first pneumatic stepper and the first fully MRI-compatible motor because it does not interfere with the electromagnetic field. The motor is comprised of entirely nonmagnetic and dielectric materials, such as plastics, ceramics, and rubbers. Encoding was performed with fiber optics so that the motors are electricity free, exclusively using pressure and light.

Six PneuStep motors actuate the robot. The PneuStep invention is based on the idea that end-to-end motion of a piston within its cylinder is always exact. This can be achieved by simply pressurizing the cylinder, which is easier than positioning the piston in mid-stroke with pneumatic-servo control. To create airflow, a remote pneumatic distributor generates pulsed pressure waves.

According to a paper published in IEEE/ASME Transactions On Mechatronics, VOL. 12, NO. 1 that describes the invention, the step motor successively collects small end-to-end motion strokes in a rotary motion. A step is made by an end-of-stroke motion. A new kinematic principle induces the step motion and de-multiplies it (gears it down) with the same mechanism. The basic motor is rotary, but the integrated gearhead can be configured for either rotary or linear output of various step sizes part/assembly, named ‚“hoop-gear.‚â€

The motor assembly includes a motor, gearhead, and incremental position encoder. A special electronic driver controls the motor with electric stepper indexers and standard motion control cards. The motor accepts open-loop step operation as well as closed-loop control with position feedback from the enclosed sensor.

Unlike other pneumatic types, the motor can easily perform accurate and safe actuation. In case of malfunction it may only stall. What‚’s more, breaking a PneuStep hose, for example, may not unwind the mechanism, which could harm the patient.

Johns Hopkins University

http://urology.jhu.edu/urobotics

::Design World::

Filed Under: Pneumatic equipment + components, Medical-device manufacture, Motion control • motor controls, Motors • stepper

Tell Us What You Think!