As serialization strategies gain ground in pharmaceutical companies, momentum is building toward defining a standard. “We’ve had more and more requests for serialization in the past two years,” said Andy Smith, sales manager at Modular Packaging Systems, a company that builds packaging machines for the pharmaceutical and nutraceutical industries. This systems integrator offers a broad spectrum of bottle filling, electronic counting and labeling machines.

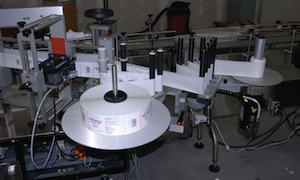

As resources for investing in modern production technology become more constrained, especially in the pharmaceutical industry, the ability to integrate machine components in packaging lines has taken center stage. The company’s systems come equipped with OEE (Overall Equipment Effectiveness) tracking and centralized monitoring systems, which use sensors on the line to collect data and determine where bottlenecks occur. In addition, the company added a labeler – the MBL-200 – to its latest product line. A particular advantage of the new machine is the ease with which it can be integrated in the bottle-filling machine. The new labeler applies pressure sensitive labels to the bottles and also inspects labels for proper batch, date and barcode data as well as ensuring that they have been applied to the bottle properly.

A Power Panel with a Windows operating system handles real-time control and integrated image processing, running Acuity vision software, in one compact unit. The system architecture is based on a POWERLINK network, which provides high-speed data exchange between the X20 I/O modules and ACOPOS servo drives, and VFDs connected through X2X Link.

B&R’s latest drive technology helped Modular Packaging Systems improve the speed and accuracy of their filling and labeling systems considerably. The output quality and accuracy of each component was increased, resulting in an overall boost to the productivity of the line as a whole. A second Power Panel provides centralized line control and monitoring, and is capable of perform-ing serialization and OEE tracking.

B&R Industrial Automation Corp.

www.br-automation.com

::Design World::

Filed Under: Factory automation, ENGINEERING SOFTWARE, Medical-device manufacture, Packaging, SENSORS, Motion control • motor controls

Tell Us What You Think!