In this two-part series, we go over the basic definition of types of repeatability and their application in linear motion and actuation applications. Part 2 covers bidirectional repeatability. (Click here for Part 1.)

Information courtesy of IntelLiDrives Corp.

As noted in Part 1, repeatability can be defined as the variation in results for a series of moves or, more analytically, the width of the dispersion about the mean for a significant number of positioning trials. Repeatability, a statistical quality, is commonly defined for a normal distribution by the dispersion width corresponding to a number of standard deviations.

Unidirectional repeatability deals with motion in one direction only. Here, we cover motion in two directions and thus must consider bidirectional repeatability.

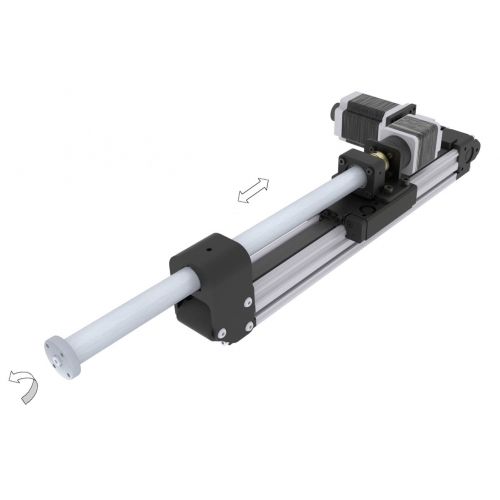

Bidirectional repeatability comes into play, for instance, in this RLTX-40 Roto-Linear actuator from IntelLiDrives.

A high level of unidirectional repeatability is relatively easy to achieve since backlash, the motion lost on reversal that contributes to bi-directional repeatability, does not affect unidirectional movement. Of course, approaching targets from a single direction sacrifices throughput times. Bidirectional repeatability is more demanding.

A high degree of bidirectional repeatability presupposes high-level unidirectional repeatability. Tolerances between drive train elements (lead screws/nuts, meshed gears, multi-piece couplings, etc.) must be closely controlled and preloads must be adjusted in order to limit backlash, which may be considered as a mechanical dead band in the motion system.

In programmable motion systems, it’s possible to remove backlash by means of a small incremental move before making normal moves in a given direction. Minimizing either the number of interacting drive train components (gear trains, belts/pulleys, etc.) or the play or looseness between components (which develops as components wear) will also reduce backlash.

In rolled ball screw systems, a backlash is typically less than 0.001 in., while high-precision ground ball screws exhibit backlash of less than 0.0001 in.

When high performance and maximum production throughput are required, bidirectional repeatability will usually be required as well.

Filed Under: Ballscrews • leadscrews, Motion control • motor controls, Motion Control Tips

Tell Us What You Think!