Betatronix has designed and manufactured precision rugged position control solutions serving the Space, Military, Aerospace and Industrial markets for over 50 years. Innovation has always been the benchmark through their legacy of custom designed solutions that have transcended the mythical perceptions of potentiometer limitations. The company’s history of partnering with their customers to leverage their strong design expertise through 3D modeling, test and problem solving has recently taken on a new level of leadership.

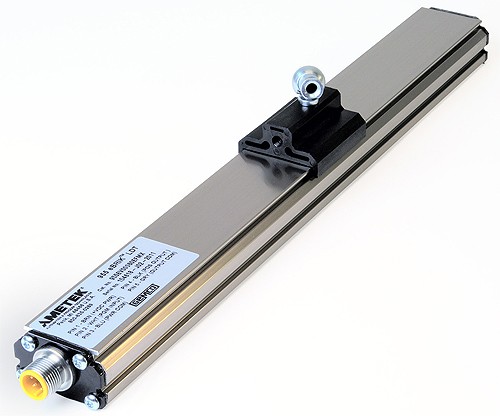

By incorporating creative rugged design methodologies, the company has cost effectively integrated mechanical solution metrics into conventional electro-mechanical potentiometer sensors to overcome system induced mechanical loads, torque and vibrational forces that have rendered competitive sensor technology ineffective and inoperable.

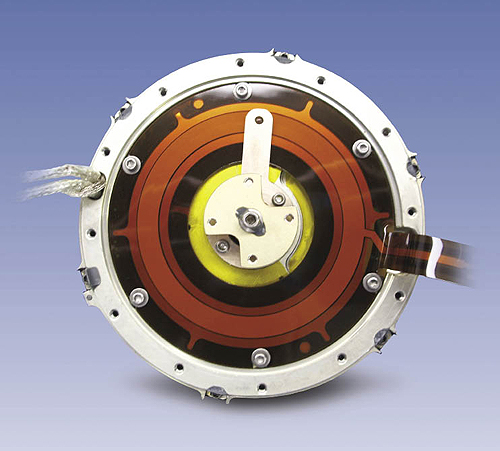

Designing for angular and direct load forces, Betatronix has integrated a rotary load-bearing ‘sensor shaft’ mounted within a precision (<0.5% linearity), vibration resistant, rotary potentiometric low power sensor. “It’s basically a heavy load-bearing rotary shaft with built-in high precision potentiometer. It can withstand 60lb radial loads and 20 lb thrust with zero axial displacement. Additionally, the unit has a low parts count with minimal electrical connections, and uses our proprietary electrical wiper design that withstands extreme vibrational conditions that maximizes reliability. The result is a ten-fold improved operational life over the competition” states Brian Rosengrant, Engineering Manager.

Designing for angular and direct load forces, Betatronix has integrated a rotary load-bearing ‘sensor shaft’ mounted within a precision (<0.5% linearity), vibration resistant, rotary potentiometric low power sensor. “It’s basically a heavy load-bearing rotary shaft with built-in high precision potentiometer. It can withstand 60lb radial loads and 20 lb thrust with zero axial displacement. Additionally, the unit has a low parts count with minimal electrical connections, and uses our proprietary electrical wiper design that withstands extreme vibrational conditions that maximizes reliability. The result is a ten-fold improved operational life over the competition” states Brian Rosengrant, Engineering Manager.

This design solves system level mechanical environmental challenges never before anticipated or addressed at the electro-mechanical component level. The alternative is to re-design the higher assembly mechanical control system or deploy expensive ‘de-coupling’ mechanisms in-line to isolate the sensor, required significant cost, system re-qualification, risk, and end unit downtime.

According to Global Sales Manager, John Taverna, “By partnering with our customers, Betatronix offers Engineering Design Services that merge system level solutions with custom position sensor requirements to create innovative products unmatched in the industry. No other position sensor technology can provide the combined benefits of our solutions.”

Betatronix

www.betatronix.com

Filed Under: Aerospace + defense, Potentiometers, MOTION CONTROL, SENSORS, MORE INDUSTRIES

Tell Us What You Think!