When QSI Corporation, now Beijer Electronics, decided to redesign a small human-machine interface (HMI) terminal, a team headed up by design engineer Bill Devenish sought to develop a simpler product to help the company become more profitable.

They used Design for Manufacturing and Assembly (DFMA) software to compress development cycles and identify ways to lower material and assembly costs while improving reliability and serviceability.

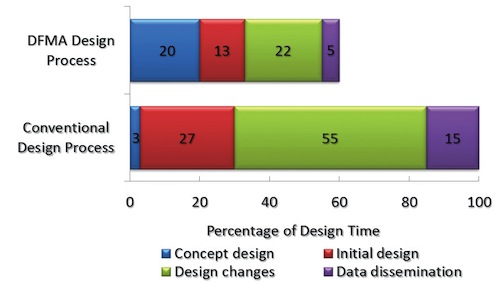

DFMA used upfront in the engineering process reduces the design development cycle by 40%.

Traditionally, the materials for the housing and structural components were made from formed sheet metal and machined aluminum. The original terminal included 31 fasteners of 13 different types. Devenish knew that adopting molded plastic for the housing could potentially reduce fastener counts while simplifying manufacturing.

The team researched materials that function reliably in harsh environments — ones that could withstand conditions ranging from arctic oil rigs to desert construction equipment to industrial applications involving contact with hot or caustic materials. They used DFMA to study how choices would impact costs, delivery time, assembly work, and other factors. The team performed tests on a few sample materials and selected an acrylonitrile butadiene styrene (ABS) polycarbonate blend. “We wanted that combination so we could lower costs while maintaining toughness and dimensional stability,” said Devenish.

The new terminal design is comprised fewer internal parts and uses a molded plastic material instead of sheet metal for its housing – making the product more light weight and easier to assemble.

As a result of the successful redesign, instead of multiple, complex, expensive metal parts and many fasteners, the new product assembly is composed of a few molded PC ABS components with integrated features such as slots, snaps, tabs, and a few fasteners. In addition, the new design replaced three printed circuit boards (PCBs) within the enclosure with one, which reduced the number of electronic components and reduced solder joint count.

Shaving design costs

DFMA includes two elements: The DFA Product Simplification module focuses on achieving parts consolidation and assembly simplification through a sequence of detailed questions about function and purpose. The DFM Concurrent Costing module calculates accurate part and tooling costs through a similar process including questions about materials and manufacturing processes.

The software provides a series of cost estimates and comparisons from the start of the product development process and continues to support design and process refinement on an ongoing basis. The cost data is based on examining existing costs, performing separate Pareto analyses, and organizing choices by part category such as fasteners and electromechanical parts.

In the QSI project, “We performed the DFMA analysis at multiple points,” Devenish added. “We used it up-front to generate initial cost estimates and throughout the development process to monitor our progress. DFMA also validated quotes from suppliers. We were able to compare actual assembly times from prototype builds to the DFMA analysis to check the assumptions of our assembly operations.”

Boothroyd Dewhurst, Inc.

www.dfma.com

Filed Under: Data acquisition + DAQ modules, ENGINEERING SOFTWARE, Displays • HMIs • operator interfaces • monitors

Tell Us What You Think!