(ROCKFORD, IL) – Pacific Bearing Company, deferred to an offline boring drill rather than CNC machinery to increase thruput on a custom steel ring bearing line. By introducing a manually operated offline drill into their production process, the company saved $100,000 and showed 26% productivity savings.

Company engineers set out to design a drill specifically for this application with the following goals in mind: make it mobile, light weight, easy to use, fool-proof setup, durable, with a small footprint, and a small budget. The drilling operation required a medium accuracy automated drill to complete the final product specifications. The composite produced debris that was not easily tolerated by conventional antifriction ball and roller bearings.

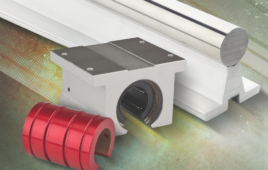

Although the concept is simple, it required a radical approach! “Really, you have to appreciate the simplicity of it all,” says Bill O’Connor, Manufacturing Engineer for Pacific Bearing Company. Dolphin Guides use proven Simplicity® linear bearing technology. FrelonGOLD® self-lubricating bearings running on the ceramic guides provide maintenance free, smooth frictionless motion.

www.pacific-bearing.com

:: Design World ::

Filed Under: Bearings, Machine tools + subtractive manufacturing

Tell Us What You Think!