Helukabel recently announced that select PROFINET and PROFIBUS cable products have earned a Power-Limited Tray Cable – Exposed Run (PLTC-ER) certification to stay ahead of the curve as industry trends change. The product specific cable types being upgraded are: PROFINET Type A, PROFINET Type B, and PROFIBUS DP.

The original PLTC certification allowed the products to extend outside of the cable tray 6 ft (1.8 m). With the upgraded PLTC-ER certification, these products can extend up to 50 ft (15 m) outside of the cable tray without additional protection e.g. conduit, armoring, etc.

The original PLTC certification allowed the products to extend outside of the cable tray 6 ft (1.8 m). With the upgraded PLTC-ER certification, these products can extend up to 50 ft (15 m) outside of the cable tray without additional protection e.g. conduit, armoring, etc.

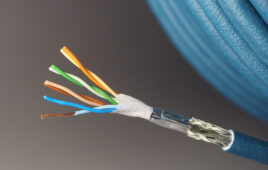

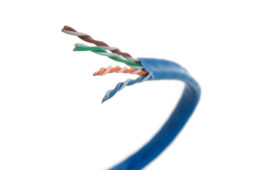

PROFINET Type A is rated Category 5e. It can be used in environments that vary in temperature between –40° and 176°F (–40°C and 80°C). The PVC jacket is flame retardant according to flame test IEC 60332-1-2 and UV-resistant according to UL 2556 Section 4.2.8.5 and UL 1581 Section 1200, respectively. Additionally, the PROFINET Type A is UL recognized under PLTC-ER 75°C according to UL 13 for the United States, c(UL)us Listing Type CMG 75°C according to UL 444 for the United States and Canada, and meets the standards according to CE and RoHS.

PROFINET Type B is rated Category 5e. It can be used in environments that vary in temperature between –40° and 176°F (–40° and 80°C). The PVC jacket is flame retardant according to flame test IEC 60332-1-2 and UV-resistant according to UL 2556 Section 4.2.8.5 and UL 1581 Section 1200, respectively. Additionally, the PROFINET Type B is UL recognized under PLTC-ER 75°C according to UL 13 for the United States, c(UL)us Listing Type CMG 75°C according to UL 444 for the United States and Canada, and meets the standards according to CE and RoHS.

PROFIBUS DP has a stranded pair and a violet outer jacket. It can be used in environments that vary in temperature between –40° and 176°F (–40° and 80°C). The special PVC jacket is flame retardant according to the FT4 Vertical-Tray Flame Test according to UL 2556 Section 9.6 and UL 1685 Section 12 to 19. Additionally, the PROFIBUS DP is UL recognized under PLTC-ER 75°C according to UL 13 for the United States, c(UL)us Listing Type CMG 75°C according to UL 444 for the United States and Canada, and meets the standards according to DESINA, CE and RoHS.

Helukabel

www.helukabel.com

Filed Under: Wire & Cable Tips