AI Technology, Inc. (AIT) claims to have solved one of the technically more challenging problems in wafer level semiconductor packaging to achieve conductive die-attach film adhesive (DAF) of 20-micron thickness.

AI Technology, Inc. (AIT) claims to have solved one of the technically more challenging problems in wafer level semiconductor packaging to achieve conductive die-attach film adhesive (DAF) of 20-micron thickness.

While DAF adhesive at the wafer level is becoming more prevalent in die-attach for memory modules in precision bonding and thin packages, thermally conductive and electrically conductive die-attach film is more limiting because of the challenging handling and performance issues for the thinner conductive DAF.

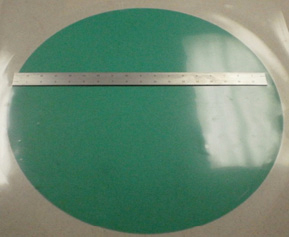

AIT is now able to produce ESP8660-HK in 20-micron thickness for power devices from microprocessors to concentrated solar die-attach modules. This new thickness marks an improvement over 50-microns thick ESP8660-HF, which was first produced in 2005.

ESP866-HF can be produced in wafer-shape die-cut format and pre-laminated on dicing tape (DDAF) format up to widths of 450 mm and lengths of 100 meters.

ESP8660-HK is also developed for high glass transition requirements to facilitate faster wire-bonding at temperatures as high as 250°C. The adhesive is molecularly engineered to reduce stress and ultimately improve the reliability of multi-chip modules (MCM) and systems in package (SIP) devices.

In addition to achieving one of the lowest thermal resistances with thermal conductivity of over 8 W-m/°K, the adhesive maintains its bond strength after 85%RH/85°C and demonstrates reliability test results after thermal cycling and shock that are not common even for traditional paste die-attach adhesives.

About AI Technology, Inc.

www.aitechnology.com

Filed Under: Semiconductor manufacture, Packaging, MOTION CONTROL, MORE INDUSTRIES

Tell Us What You Think!