Sensor failure is the single biggest cause of weld cell unplanned downtime. Impact, heat, and slag are the culprits.

You can eliminate these problems and extend sensor life from hours to months with very little up front cost. And your savings can run to hundreds of thousands of dollars per year. These sensors and their connections, with their protective covering, will last for months with no maintenance issues.

Choose the right sensor

Only sensors and mounting blocks designed to withstand the welding environment will survive for extended periods. In weld fields, use only one-piece steel bodied weld field-immune proximity sensors with PTFE coated faces. TPE cabling is best for weld cells.

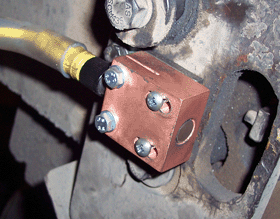

Eliminate load impact

You can protect sensors from impact by putting them in bunker blocks made from aluminum or steel. The blocks help protect sensors from heat spikes as well.

Heat and Slag; before and after

Unprotected sensors and cables can fail in the weld cell environment in a matter of hours. Slag not only builds up on the sensor, it destroys the cabling as well, weighing it down and pulling it from the sensor. The answer is silicone tubing and wrap, which seals the sensor and cabling, and in one step provides total protection from slag build up, heat, and general deterioration. The productivity gains from this level of protection are worthwhile in terms of less downtime, maintenance, and higher production.

By Tom Draper

[email protected]

Balluff

www.balluff.com/welding

::Design World::

Quick tips for sensors in weld applications

You will ensure long sensor life if you following these tips

1. Use sensors designed for weld cells

2. Use TPE cabling

3. Use bunker blocks

4. Use metal mounts

5. Use TPFE tubing and wrap

Filed Under: FASTENING • JOINING • locks • latches • pins, SENSORS

Tell Us What You Think!