Un-lubricated metal race bearings are typically used in applications with low loads and minimal movement. In these applications, ball discoloration, with portions of the ball turning black or brown, indicates that lubrication is required. In lubricated applications, such markings indicate a greater amount, frequency, or grade of lubricant is required. With increasing loads, lubricant film integrity decreases, to the point where parts have metal on metal contact, and in worst case, overheat and gall. As loads increase, the value of the ptfe lined alternative increases. An unloaded non lined part exhibits no breakaway torque or force required to initiate movement at rest. As loads overcome the strength of the applied lubrication film, the breakaway torque increases. Lined bearings typically have a pre loaded fit or breakaway torque. With light applied loads, care must be taken to determine if this torque will impede proper action of the assembly. However, as loads increase, a lined bearing will actually have a lower operating torque than an unlined bearing as the point where the lubricant film is compromised is approached and then surpassed.

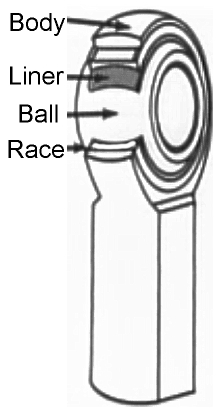

Cross sectional drawing of PTFE lined bearing showing self

lubricating liner bonded to raceway.

Beyond the noted benefits, lined bearings are also maintenance free. With lubrication delivery part of the liner system, supplemental lubrication requirements are eliminated.

www.aurorabearing.com

::Design World::

Filed Under: Bearings, Motion control • motor controls

Tell Us What You Think!