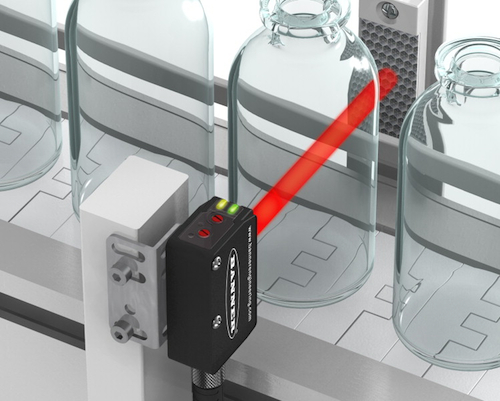

Banner Engineering Corp. introduces the Q26 Series photoelectric sensor to its line of clear object detection sensors. Featuring a polarized retro coaxial design, the Q26 is an ideal solution for difficult clear object detection applications, such as filling and bottling machines, flat glass or LCD manufacturing, pharmaceutical vials or bag filling machines, or any high-speed application where positioning is critical. With its compact cubic shape and coaxial optics, the Q26 is able to fit in tight locations. The cubic shape with 20 mm mounting hole spacing enables quick installation in tight spaces, and the coaxial optics allows the sensor to operate over a wide range of distances with the reflector mounted as close as 5 mm for space constrained applications.

“Banner has several sensors capable of reliable clear object detection, but the Q26 Series is optimized for clear object detection, with a design focus on simple user set-up and adjustment,” said Dennis Smith, Technical Marketing Manager at Banner Engineering. “The Q26 delivers both the sensitivity required for reliable clear object detection and the robust rejection of light from mirror like objects to prevent a false detection. The coaxial optical design delivers the additional benefit of precise leading edge detection, making it useful for many high speed applications in bottling, canning, and packaging industries.”

Several features of the Q26 Series help distinguish it between other photoelectric sensors with clear object detection capabilities. The Q26 includes a LO/DO switch to control the output type, and a single turn potentiometer to adjust the detection sensitivity. The Q26 includes a Health Mode output for application monitoring. The sensor operates on 12-30 Vdc with a response speed of 250 microseconds. Finally, the sensor is protected against damage from accidental mis-wiring during installation and transient voltage spikes during operation.

Banner Engineering Corp.

www.bannerengineering.com

::Design World::

Filed Under: SENSORS, TEST & MEASUREMENT

Tell Us What You Think!