By Thomas Hart, President, Testra Corporation, Tempe, Ariz.

“SoftStep” microstepping technology removes the noise and vibration problems from stepper motors.

Stepper motors continue to be one of the most common motor technologies used in many industrial applications, ranging from electronic printers and disk drives to aircraft controls and many CNC and automation applications. One of the major reasons for this is the use of microstepping drives, which have improved the smoothness and accuracy of stepper motors.

Yet, for many users, such as manufacturers using CNC equipment, microstepping technology can still have some drawbacks. Despite the prevalence of micro-stepping technology, stepper motors are still subject to vibration, noise and harmonic resonance issues because of the way they are driven. Many PC-based control systems and PLCs do not have the resolution and speed to take full advantage of the capability of the technology. Legacy systems used half-step control for step motors and have not been easily upgradable to take advantage. Even today’s systems using microstepping motors can break tooling, such as bits, when operating at higher speeds, and often have chatter problems that create flaws when cutting arcs or circular shapes.

However, these drawbacks have largely been overcome with the development of SoftStep, a microstepping technology that can virtually eliminate noise and vibration that were problematic in the past. With SoftStep, a stepper motor drive is approaching the level of smooth performance of continuous rotation motors while still being a much lower price option for machine builders.

SoftStep technology converts lower resolution step commands into ultra-fine microstepping (256 microsteps per motor step). It ramps speed up and down to track the input steps to create a smooth motion without the traditional stepper clicking, buzzing or whining noises at low speeds.

SoftStep Fundamentals

The basic idea behind the SoftStep drive involves placing an input rate into the drive, which is then converted into a motion vector that tracks the input step rate. This results in the input step commands producing extremely smooth motion, as long as the input command stream is also smooth even though much coarser. The velocity is maintained by first starting out at a preset starting speed, then looking for the next input step pulse. It uses that time interval to set a new speed and continues with the process. The motor is then driven using PWM signals using patented control algorithms to control the current in the windings. The chip used in the drives containing the special algorithms was developed in-house.

Another important design element was that the motor’s response be linear to the input positioning step commands. Ideally, a sine wave drive to a motor designed for microstepping would give that result. In reality, as the current increases, the magnetics begin to saturate. This causes the motor to lose force and makes the response non-linear, which results in both a position and torque ripple at harmonics of the input sine wave. This can then greatly aggravate natural resonances present in the motor and the coupled machine, and in the worst case lose control of the motor with the loss of steps. The SoftStep technology can minimize this by modifying the drive waveform to counteract the motor non-linearity.

The graph shows the mechanical position error of an unloaded step motor driving a flywheel at a slow speed of about 7.5 full steps per second. The small yellow markers are 1/10 step while the larger markers show the full step, four of which make up one pole of the step motor. The red graph shows the position error while being driven by a non-compensated SoftStep driver, while the blue graph shows the position error using a standard 1/10th microstep driver. The large slow error is caused by the non-linear response of the motor itself which can be compensated for with the SoftStep driver.

Lastly, there is the issue of the zero-crossing point. Most microstepping drives have a large error around the zero crossing point when the current in the motor windings changes phase. Oscillations also often occur in this control region along with a noisy transition. The SoftStep design uses a few tricks to sort this out; by offsetting the current waveform by half a microstep, the signal never has to be controlled at zero but at plus or minus 1/512th of the rated motor current. This precise control would not be possible without dynamic collaboration as well, auto calibrating the zero crossing point of the measurement system of the drive.

The combination of this technology yields a drive that is smooth and accurate and that can be used on all types of stepper motors. Because of it’s inherent precision, it’s also an ideal selection for driving linear stepper motors.

Application Successes

A significant and noticeable result of the new SoftStart technology is an obvious reduction in noise and vibration, as end-users confirm.

“The stepper motors were so quiet that I thought the machine wasn’t running,” says Matthew Dunne, President of Align-Rite Tool Company (Tucson, AZ). Align-Rite makes a broad line of CNC routers and mills and other tools used by fabricators in the woodworking, jewelry, metalworking and solid surface industries.

“One of the reasons we’ve switched to Testra’s SoftStep drive systems is that you get really accurate, very quiet drives compared to other ones,” Dunne explains. “It also allows you to cut faster because the drives virtually eliminate the vibration, so you get a much smoother movement on your X, Y and Z axes.”

The graph shows the difference in error between a stepper driven with a SoftStep ss483 drive and a system not using SoftStep. The SoftStep ss483 has no discontinuities in the current control, which allows precision correction to be applied to the waveform to match the motor characteristics for position and torque.

Dunne adds that customers are satisfied with the SoftStep drives that are installed on Align-Rite’s wood routers because they’re capable of going faster with smaller bits with greater accuracy. Also, with the vibration problem removed, there is much less tendency to break bits.

“When you get down to some of our smaller bits – people doing pool cue inlays and things like that – you have to have a CNC router that can run at a fairly high speed, but very smoothly,” he says. “For applications such as jewelry or where you have expensive Corian inlays you must have a very smooth stepper system so that you don’t have any chipping from vibration.”

Another success story comes from CAMaster CNC, a Cartersville, GA manufacturer of CNC routers, lasers, and plasma cutters. They also use turnkey Testra SoftStep drive packages on their three-axis Stinger CNC router. Designed for hobby and light industrial use, the Stinger is a three-axis, bench-top router designed to incorporate the same quality features as its industrial-duty counterpart, the Cobra Series servo-controlled router line.

“We wanted the Stinger models to offer the same accuracy, quietness and smoothness built into our larger routers, but with a stepper motor,” explains Joey Jarrard, CAMaster co-owner. “But most steppers produce the ‘growl’ noise that does not sound professional. So, after trying a few other driver packages, we chose a SoftStep plug and play drive system that was very quiet, smooth and accurate, almost like a more expensive servo system.”

The model CAMaster chose was a 4-axis system complete with power, drivers, connectors, and PC cables. Jarrard says because the drive system comes with four axes it is like a bonus feature for his customers.

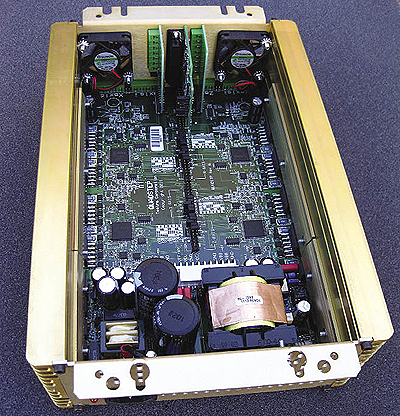

Testra’s SoftStep driver modules come in a variety of sizes, such as the ss483 Series, as well as the ss4x483 quad-step system, a four-axis drive system including power, I/O interface to the machine being controlled, and an interface to a PC for control. The ss4544 system is a stand-alone unit with an embedded motion control computer and CNC machine control firmware.

“The Stinger is a three-axis machine, but we can upgrade to include a lathe on our machine. Since the SoftStep drive system comes with four drives, we already have an extra drive available. So, the customer can install their fourth axis machine without doing any additional wiring. Also, if a customer is not using the fourth axis, if one of the three drives goes out in the future, they have an extra drive available to get them back up and running in a matter of about one minute,” Jarrard says.

Stinger customers range from serious hobbyists to light industrial manufacturers of guitar bodies and cabinetry of world-renowned manufacturer of stadium speaker systems. Jarrard says the lack of vibration from his routers stepper motors allows these high-quality products to be produced without having to smooth out the nicks and other chatter spots that are often caused by stepper motors.

“Even if you’re dealing with a couple of thousandths of an inch, one cut and you’re done,” he says.

Jarrard adds that his SoftStep controlled stepper motors are also cool to the touch, unlike many others.

“The drive is still holding when it’s not moving, but it’s not cranking out the maximum amperage that will make the motor hot,” he says. “That makes it safer for the customer because they’re not going to get burned as they might by a motor that is 130 or 140 degrees. Running cool also affects the longevity of the motor. I have seen motors with other drives burn out in a year or so because the heat causes the motor’s copper windings to melt together. So, with the motor running cool it could last easily twice as long.”

Testra Corporation

www.testra.com

::Design World::

Filed Under: Drives (stepper) + amplifiers, Motion control • motor controls, Motors • stepper

Tell Us What You Think!