If you hear a clanging sound coming from your car’s suspension, it’s not a good thing. Or, if you bottomed your springs and hear a metallic grinding noise, it probably means you are at risk of bending or breaking some part of your suspension. Your bump stops will need to be replaced. They serve as a suspension cushion to keep metal parts from coming together or from traveling too far which can cause damage to the chassis or suspension.

For NASCAR Cars of Tomorrow (COT) spring and bump rubber ratings are an important part of suspension performance. The size and stiffness ratings with shock travel allow the front end suspension to move while turning a corner on a race track. Having good data acquisition on spring and bump stops can ensure that the suspension operates properly and within optimal range.

Championship racing actuation in the real world.

To address this issue, Earnhardt Technologies Group (ETG) recently developed its own advanced Spring Bump Stop Rater (SBSR) system that emulates the vertical forces applied to the springs and bump stops. Prior to the SBSR, automotive engineers and race crews used traditional hydraulic testing systems that were noisy, messy, and inaccurate. They lacked the necessary precision needed for repeatable increments to deliver complete motion control.

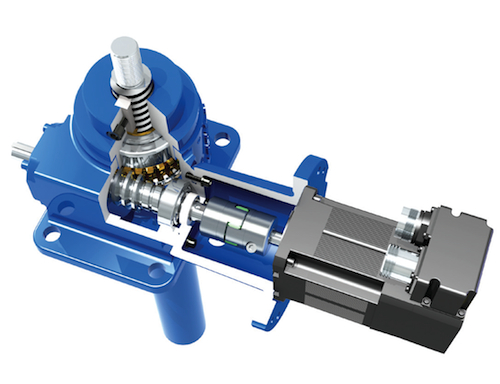

To develop its SBSR, ETG turned to Nook Industries, maker of the ActionJac Screw Jack system. The ActionJac Screw Jack is a worm gear-driven mechanical actuator with load handling capacities from 1/4 ton to 100 ton and 5 kN to 200 kN.

The powerful ActionJac Screw is worm-driven, self-contained, and fully sustainable.

The 5-ton ActionJac Screw Jack system at ETG provides up and down motion in small, precise and repeatable travel increments to test the vertical forces acting on the spring and bump stops. The SBSR uses a top load cell that measures the load and displacement as they compress the bump stop (or coil-bind the spring). The ActionJac and its servo motor control the up and down motion within controlled settings and test configuration. The ActionJac is also self-locking and holds to a specific set point.

The machine features a lifting shaft made of alloy steel with a minimum tensile strength of 95,000 psi. It is manufactured with a lead accuracy of approximately 0.004-in./ft. It provides a 24:1 gear ratio and a reliable load handling capacity of 500 lb/in. of travel on the repeatable spring bump stop test. The product incorporates a rugged worm gear set arrangement that uses an alloy steel worm, which drives a high strength bronze worm gear (drive sleeve). The worm shaft is supported on tapered roller bearings with external seals to prevent loss of lubrication.

Nook Industries

www.nookindustries.com

Filed Under: Actuators, Automotive, MECHANICAL POWER TRANSMISSION, Motion control • motor controls, Shocks + vibration control • gas springs

Tell Us What You Think!