By Drew Devitt, Chairman and Chief Technology Officer, New Way Air Bearings, Aston, Pa.

To capture an image of a heart at its most quiet moment requires incredibly fast motion on the part of CT scanners. Air bearings help the scanner deliver the needed speed.

<

Although they are tried-and-true, stable, and cost-effective, traditional ball-bearing systems used to support the rotating gantry ring in Computed Tomography equipment have inherent limitations. By their nature, these bearings must contact the ring. This contact causes friction, which results in numerous undesirable effects including noise, heat, wear, and vibration. Most of all, though, contact constrains speed and reduces both temporal accuracy and bearing life.

As a leading manufacturer of CT equipment worldwide, Philips Healthcare knew that the current range of contact bearings were not going to be the answer in achieving the rotation speed required by its clinical partners interested in imaging the heart. With contact bearings, rotation times for large format CTA scans (using 1.68 m rings burdened with approximately 3,000 lb) were limited to 0.33 seconds per revolution, primarily due to this inherent friction.

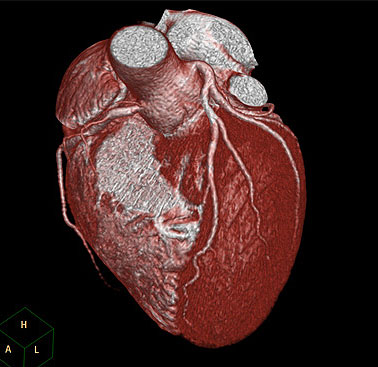

The procedure to image the heart and see the details of the vascular system that feeds the heart wall with oxygenated blood is technically demanding. This procedure, known as Cardiovascular Computed Tomography Angiography or CCTA, is an emerging application. It can evaluate the presence of occlusive disease and the efficacy of subsequent interventions in coronary vasculature. There are challenges inherent in the imaging of the coronary arteries associated with the motion of the heart. The challenge in achieving high image quality and visibility of sub-centimeter coronary vessels is to time the exposure to the most quiet moment within the cardiac (heart beat) cycle. The success of the CCTA examination of the coronary arteries is dependent upon the optimization of a number of enabling technologies, most importantly the ability to achieve higher rotation speeds.

Image of the coronary arteries in a patient with a heart rate of 80 ± 6 bpm. Images were acquired in end-systolic coronary rest phase using a 0.27 second rotation time. Images courtesy of Washington Hospital Center.

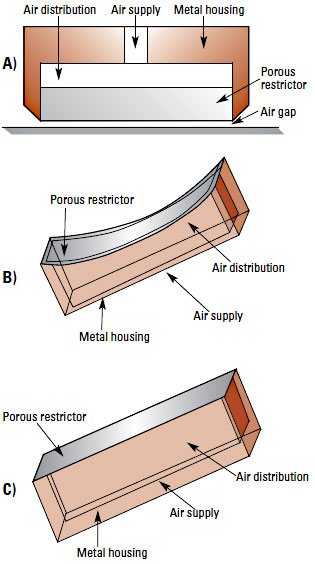

Plain Porous Air Bearing

(a) Schematic of air-bearing pad

(b) illustration of radial pad

(c) illustration of axial pad

According to Philips Healthcare CT Product Manager Robert Popilock, their clinical partners interested in performing CT examinations of the heart requested a system capable of faster rotation speed to improve the likelihood of capturing a ‘snapshot’ of the vessels supplying blood to the heart wall at the most quiet state.”

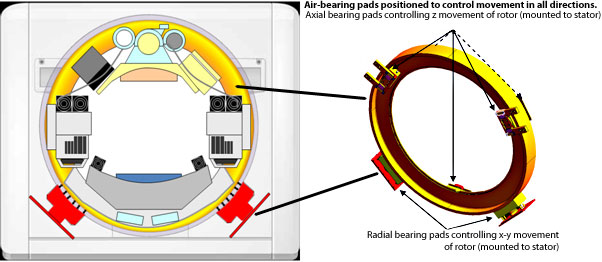

Philips engineers began exploring a non-contact bearing option, ultimately settling on the use of radial air bearings from New Way Air Bearings of Aston, PA, USA. These porous media air bearings have long been used in other rotary and linear motion applications across an array of industries, notably semiconductor, flat panel display, and photovoltaics manufacturing. Philips recently introduced these air bearings on its flagship CT scanner platform, The Brilliance iCT.

The Brilliance iCT scanner, from Philips Healthcare, uses AirGlide Technology to capture images of the heart during the two phases the heart rests.

The non-contact air bearings use a microscopic film of air instead of a ball bearing as the ‘virtual’ point-of-contact between the rotation ring and the static, non-rotating frame. The surface of these Porous MediaTM bearings consists of millions of sub-micron sized holes through which air is evenly distributed. Conceptually, this porous carbon pad is the substantially more sophisticated equivalent of an air hockey table. The non-contact surface virtually eliminates friction and is capable of achieving very high rotation speeds; enabling Phillips engineers to reduce CT scan time while improving temporal resolution.

In late November 2007, Philips introduced a prototype of the AirGlide air-bearing technology at the Radiological Society of North America (RSNA) Show in Chicago, Ill. In development for more than six years, AirGlide technology floats the Brilliance iCT gantry ring on just a few microns of air, allowing a frictionless and stable rotation, while maintaining focal-spot-to-detector element integrity at very high speeds. The radial air bearings enabled Philips to achieve a rotation time of 0.27 seconds; almost four revolutions per second versus three for the conventional contact bearings.

Using the AirGlide system, the Brilliance iCT has achieved consistent higher rotation speeds of 220 rotations-per-minute, capable of delivering the improved temporal resolution desired by Philips and its clinical partners.

Improving reliability in the field was another clinical requirement for Popilock. The Philips engineers believed that a non-contact surface that could reduce friction would be ideally suited not only to deliver the higher rotation speeds necessary to achieve the shortest acquisition time, but also the stability required to reduce the effects of vibration associated with the operation of ball bearings at high speeds.

The Brilliance iCT should operate for 15 years without changing a bearing ‘pad.’ Plus, the air bearings function without contact, so there is no wear. In fact, maintenance is reduced because there are no requirements for lubrication.

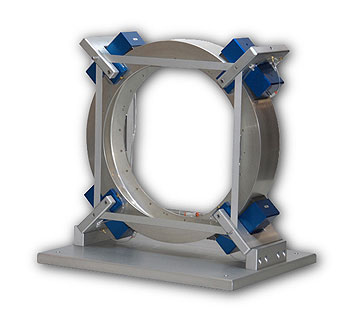

Prototype of air-bearing gantry design.

Since launching AirGlide as part of the Brilliance iCT platform, Philips has validated its level of performance in the field with over 100 installations worldwide.

Fletcher Allen Health Care (FAHC), a level-one trauma center located in Burlington Vt., has added the latest Philips CT featuring this air bearing system to improve their ability to evaluate patients with chest pain and higher heart rates. Such studies benefit from faster gantry rotation and shorter examination times. According to Dr. George Ebert, Director of CT at FAHC, the total scan times (with the Philips iCT) for the most demanding examinations are only seconds long.

Of course, radial air bearings aren’t the only significant system enhancements in the Brilliance iCT system. Leveraging the mature and stable design of the MRC x-ray tube, the new iMRC tube enables high power (120 kW), shortshot imaging, and focal-spot integrity at high rotation speeds. A Smart Focal Spot improves image quality through simultaneous deflection in the X- and Z-axes to double the samples in every rotation. The resulting visual acuity is extremely high, even for very small sub-centimeter blood vessels.

But the centrifugal limitations of other system components constrain the maximum rotational speed of the current 256-slice MDCT scanner to 220 rotations per minute (0.27 seconds rotation time). The air bearing design itself permits a rotation speed of up to 400 rotations per minute (0.15 seconds rotation time). As the balance of system components become more robust, future scanners that build on Philips AirGlide capabilities will be able to image an even wider patient population — with higher heart rates and less sensitivity to heart rate variation — than is now possible.

Discuss this on the Engineering Exchange:

New Way Air Bearings

www.newwayairbearings.com

Filed Under: Bearings, Medical-device manufacture, MECHANICAL POWER TRANSMISSION, Motion control • motor controls

Tell Us What You Think!