Use your PLC programming experience to program groov EPIC.

Ready to write a control program for your groov EPIC, but not sure how to get started? With three options to write your control program–PAC Control, the easy-to-learn flowchart language, the Linux-based Secure Shell (SSH) to run your custom program, and CODESYS, an IEC-61131-3 compliant language–which do you choose?

If you have PLC programming experience, you may already be familiar with the languages used by CODESYS such as ladder logic and structured text. Next, you might be wondering: What libraries do I need? How do I configure my controller and I/O? And, how do I write the logic? Why else should I use CODESYS? No problem, let’s explore this.

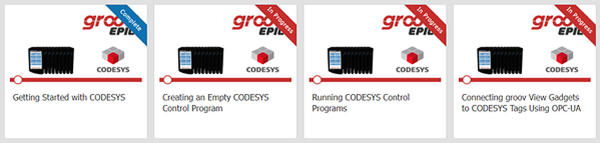

First, OptoU has step-by-step lessons to help you write your CODESYS control program. The lessons cover:

- Getting started

- Installing the libraries needed to recognize groov hardware

- Configuring a project with your controller and modules

- Creating and running program logic with Structured Text and Ladder Logic

- Connecting CODESYS tags to a groov View HMI

The lessons refer to a groov EPIC Learning Center, but it’s not a problem if you don’t have one. Adapt the lessons for the groov EPIC and groov I/O hardware that you do have.

As you work your way through the lessons, the end result is a working project and a method to develop subsequent projects.

Another reason you may want to use CODESYS is because of its open source nature. It can import any OpenPLC compatible code, saving you development time.

And finally, many opt to use CODESYS because it supports several protocols on your groov EPIC. Here are just a few:

- CODESYS BACnet SL

- CODESYS EtherCAT Master SL

- CODESYS CANopen Manager SL

- CODESYS EtherNet/IP Adapter (Slave) SL

- CODESYS EtherNet/IP Scanner (Master) SL

With all these advantages–your PLC programming experience, CODESYS’ flexibility to import any previous OpenPLC projects, support for several protocols, and lessons that result in a working program and HMI, CODESYS just might check all the boxes when deciding how to program you next control program on your groov EPIC.

Filed Under: Opto 22 Sponsored Content