One of the latest advances in automated conveyance involves reinventing the way packages moved from point A to point B. The Intralox patented Activated Roller Belt (ARB) equipment brings the benefits of modular plastic belting to conveyance applications to enable greater flexibility, higher throughputs, reduced footprint, and simpler control.

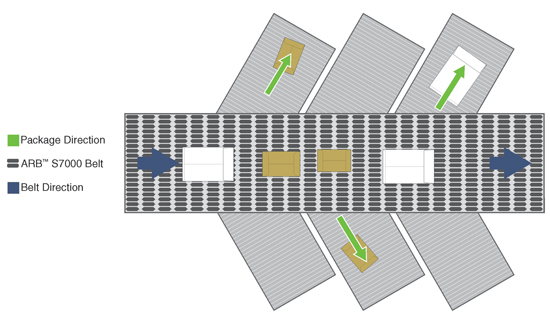

ARB technology makes it easy to work with conveyor systems that have multiple requirements. This drawing illustrates packages being sorted on the ARB S7000 belt.

To maintain control and increase the flexibility of the ARB equipment, Intralox uses multiple STM/SWM integrated stepper motor packages (motor, drive, and control in one package), designed and manufactured by Applied Motion Products.

STM/SWM integrated stepper motor packages from Applied Motion Products have been designed for user flexibility.

Major advantages and features are gained from having a single package solution. For example, the stall detection and stall prevention features of the STM/SWM package allows the ARB to operate each stepper motor in a similar way to operating a servo motor—eliminating the concern over stepper motor “slip.” Further, the Q-Programming feature of the STM/SWM allows the user to create custom operations. This allowed Intralox to develop a “variable following” technique that provided efficient, flexible positioning, plus allowed them to easily modify the motor operation as required.

The configurable operational modes of the STM/SWM integrated stepper motor further supported the Intralox designers’ need to match the proper operational mode to the requirements of each specific product type or application.

The most common ARB electro-mechanical assembly consists of a “rack and pinion” type design. The Applied Motion STM/SWM motor is coupled to the “rack” component directly, or indirectly, with a ballscrew. Motor rotation causes the “racks” to operate the “pinions,” which in turn cause the actuated rollers embedded in the ARB belt to spin as required. This causes the product being conveyed by the ARB belt to move in a “vectored” direction at preprogrammed velocities. Depending on customer requirements, varying combinations of mechanical transmission and motor control methods can range from a simple pneumatic point-to-point emulation to a high-precision networked variable position solution.

Most of the ARB technologies use an operating range of -30.0 to +30.0 degrees (ARB module rotation), where 1 mm of rack movement equates to 5.79 degrees of ARB module rotation. So, when using a 10 mm lead ballscrew, motors can be programmed for a full-span movement of 1.2 revolutions (12 mm of ballscrew movement). This 12 mm of movement yields 69.48 degrees of total rack movement (12 x 5.79 = 69.48). Additionally, 9.48 degrees of “extra range” is used for backlash compensation and electronic zero calibration. Commanded positioning units are 0-12000, which produces a positioning precision of roughly 0.005 mm per positioning unit (0.033 rotational degrees). If the motors are operated at a velocity of 16 rps, with an accel/decel of 600 rev/sec2 it will yield a full-range movement (-30 to +30) in about 100 msecs, and a half-range movement (30 degrees) in about 64 msec. Depending on the configuration, torque values can easily be calculated. For example, an SWM24X-3 (at 48 Vdc) will produce about 200 oz-in. (at 16 rps). When using a 10 mm lead ballscrew, it will produce a maximum of about 200 lb-ft of thrust. Getting to the proper combination of speed/torque/gearing continues to be an iterative process.

The EtherNet/IP feature of the STM/SWM package implements a 4 msec RPI (update) to networked motors, which allows the ARB equipment to perform at high speeds with precision.

An analog signal provided to each ARB actuator typically comes from a central PLC for an update cycle of 2 msec. However, analog signals are prone to electrical noise and because of the unique design of the conveyor mechanisms, the slightest analog signal drift can cause errors in how packages are handled on the conveyor.

The challenge of a new and improved conveyor system was to develop a motor and actuator assembly that could position as rapidly as the analog control system (or nearly as rapidly) while eliminating the deadband issue and therefore increasing overall system accuracy. Intralox determined that while the analog system could update target position every 2 msec, this was faster than necessary for the majority of applications and that updating target position every 4 msec would be sufficient.

Each actuator moves only a short distance, but through an innovative mechanical design, the short-stroke actuator can be used with a variety of conveyor widths from as little as 1 ft and all the way up to 8 ft across. Further compounding the situation is that the motors are located throughout the length of a conveyor section—sections up to 200 feet long can have as many as 100 motors on it—so the analog signal wires from the central PLC to each of the motors can be long. These cables provide substantial surface area to pick up ambient electrical noise, which in turn makes the drift problem worse.

To overcome this situation with an analog control scheme, Intralox implemented a deadband algorithm into the step motor controller so that when commanded to be at rest the actuator is not dithering, causing the actuator mechanism to be out of position. Additionally, the deadband must be fairly large so that even in the noisiest electro-mechanical environments, the position control of the motors and actuators will be stable.

Using the EtherNet/IP feature of the Applied Motion Products integrated motors, Intralox replaced the noisy analog signal with a digital value, thus eliminating all of the analog noise issues.

The end result was a conveyor system capable of handling packages in a wide variety of configurations. ARB technology is consistently designed into applications where the handling of packages need to be aligned, turned, merged, sorted, singulated, and more, for industries such as food processing, meat, poultry and seafood processing, beverage handling, can manufacturing, baking, case and box handling, and other types of packaging.

Intralox LLC

Intralox.com

Filed Under: Material handling • converting, Motors • stepper

Tell Us What You Think!