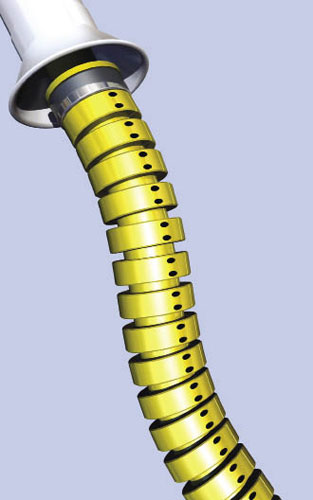

To prevent offshore oil pipes from over-bending at the interface between flexible and rigid structures, bending restrictors are usually installed. Trelleborg makes bend restrictors that are made up of a number of interlocking elements, which react when subjected to an external load, locking together to form a smooth curved radius. This radius is chosen to be equal to or greater than the minimum bend radius of the pipe that it is applied to. Once the elements have locked together, the bending moment present is transferred into the elements and back through a specially designed steel interface structure into the adjacent rigid connection, therefore protecting the pipe from potentially damaging loads. The company will provide NOV Flexibles with 25 polyurethane (PU) vertebrae bend restrictor assemblies for static flow lines on the field development and production expansion of the Parque das Baleias oil field, offshore Brazil.

To prevent offshore oil pipes from over-bending at the interface between flexible and rigid structures, bending restrictors are usually installed. Trelleborg makes bend restrictors that are made up of a number of interlocking elements, which react when subjected to an external load, locking together to form a smooth curved radius. This radius is chosen to be equal to or greater than the minimum bend radius of the pipe that it is applied to. Once the elements have locked together, the bending moment present is transferred into the elements and back through a specially designed steel interface structure into the adjacent rigid connection, therefore protecting the pipe from potentially damaging loads. The company will provide NOV Flexibles with 25 polyurethane (PU) vertebrae bend restrictor assemblies for static flow lines on the field development and production expansion of the Parque das Baleias oil field, offshore Brazil.

The use of polyurethane restrictors brings a number of benefits when compared with steel. Installation and maintenance of the assembly is less time-consuming, with lower whole life cost, as plastic does not corrode or need protection with platings, paint and anodes. Another benefit is its reduced weight, making it neutrally buoyant in water. This means there is considerably less stress applied to the flow-line and adjacent parts of the subsea structure during both installation and service.

The P-58 FPSO, which operates on the Baleia Azul field in the Parque das Baleias area, north of the Campos Basin, is moored 48 miles / 78 km offshore in a water depth of 4,593 ft / 1,400 m, and is expected to last for 25 years. Oil production comes from 19 satellite wells connected individually to the unit and is expected to commence during the first quarter of 2014.

Trelleborg

www.trelleborg.com/offshore

Filed Under: Uncategorized

Tell Us What You Think!