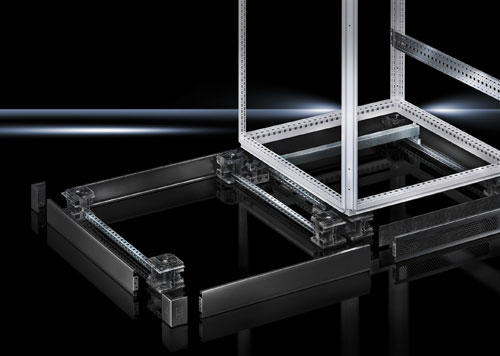

The new Flex-Block plinth/base assembly is designed specifically for Rittal’s lineup of free-standing enclosures, including its TS8, SE8, CM, TP and PC units plus its latest TS IT server/network enclosures, as well as the latest generation of liquid cooling packages.

The Flex-Block design makes it possible to quickly clip together the plinth/base components and attach accessories like casters, leveling feet and cable management pieces without special tools. They can be bayed together with a unique tool-less baying clip. Moving an enclosure is now much easier either in its configured form or empty just by removing the plinth/base trim. The units are available in symmetrical increments to match enclosure width and depth measurements.

The new base/plinth system comprises four corner modules and covers made of strong, fiberglass reinforced plastic, plus sheet steel side trim panels. The modular design and increased assembly space allow the four corner pieces, which support the entire weight of the enclosure, to be quickly and easily fitted underneath the enclosure right from the start. Without the trim panels in position, the units can be transported using a lift truck, for placement at its final destination. Once the enclosure is configured and placed, the trim panels are simply clipped into position on the base/plinth. Hexagonal slots in the base accommodate adaptor sleeves for stacking base/plinths up to 8 inches.

The 4-inch (100mm) high plastic corner modules are designed for loads of more than 3,100 pounds and can be stacked if an additional height is needed.

There’s a space-saving cable routing design in the base/plinth that leaves more space for interior installation of the enclosure. When configured with a punched rail, cable management pieces can be clipped into position from outside or inside.

The Flex-Block System brings a host of features to new and expanding installations, including:

- Fast, tool-free assembly – can be completed in as few as 30 seconds

- Quick, convenient transportation of enclosures

- Modular design to fit TS8, SE8, TS IT, CM, PC and TP enclosure systems

- Rails can be clipped into place

- Units can be bayed with a simple clip application

- Flex-Block may be retrofit to existing installations

- Flexible installation options for cable management

- A load capacity of more than 3,100 pounds

- UV resistant and UL flame rated material

Rittal Corporation

www.rittal.us

Filed Under: Cabinets • enclosures • control panels, ELECTRONICS • ELECTRICAL

Tell Us What You Think!