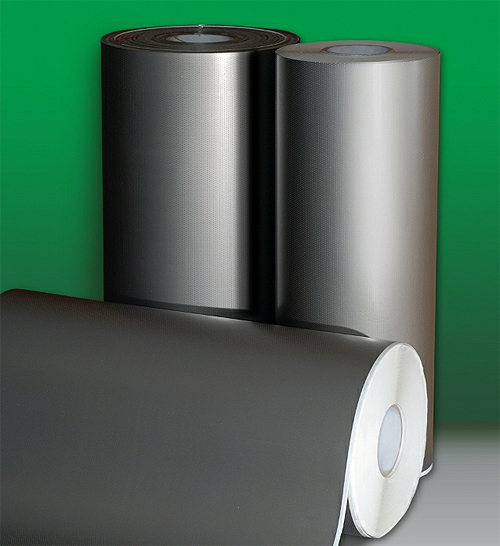

Rogers Corporation’s (NYSE:ROG) High Performance Foams Division has introduced a new problem-solving material for handheld mobile devices—Condux Plus™ electrically conductive foam. Even in the most complex, compact handheld electronic designs, Condux Plus materials feature excellent electrical conductivity, consistent mechanical properties, and outstanding electromagnetic (EM) shielding capabilities, allowing them to serve as reliable grounding pads for handheld devices in need of enhanced conductivity and shielding performance.

Condux Plus materials from Rogers Corporation provide excellent electrical conductivtity, consistent mechanical properties and outstanding EM shielding capabilities.

Condux Plus materials, available in several different thicknesses (0.33, 0.53, and 0.73 mm), are designed to provide consistent and reliable connectivity while also offering excellent mechanical stability over time and temperature. The typical compression set for 0.021-in.-thick (0.53-mm-thick) Condux Plus foam, for example, is only 2.5%. This material helps maintain the electrical integrity of the most complex mobile and handheld designs, forming reliable electrical connections and delivering necessary conductivity whether uncompressed or fully compressed.

Rogers Condux Plus foam also serves as an excellent EM shielding material, with superb shielding effectiveness (SE) over a wide operating frequency range of 200 MHz to 10 GHz. Condux Plus materials have been tested per IEEE-299 methods to provide a minimum SE of 60 dB, effectively reducing the power of EM fields by more than 99%.

Condux Plus electrically conductive foams are RoHS and REACH compliant, and will not deform with processing, yielding straight edges with die cutting. The foams can be stacked for filling gaps while maintaining high levels of conductivity and shielding.

Rogers Corporation

www.rogerscorp.com/hpf

::Design World::

Filed Under: Materials • advanced, ELECTRONICS • ELECTRICAL

Tell Us What You Think!