By Joe Gorse, Electronics Engineering Editor

“We were looking for heavy duty gearing with less backlash than the spur gear drive we were using previously,” said Michael Fortier, President of Mikrolar, as they sought to improve their rotopod robots. The former gearing set used a spur gear and a motor, which was subject to backlash and did not provide sufficient precision for some of the more demanding robot applications.

The R-3000 has a Nexen Ring, THK rail, and Hephaist joints which can apply accelerations of up to 2 G.

The rotopod consists of parallel link manipulators that use an assembly of struts which provide six degree-of-freedom motion. Rotopods have been used for flight and driving simulators, industrial positioning, joint testing, and bio-medical motion studies.

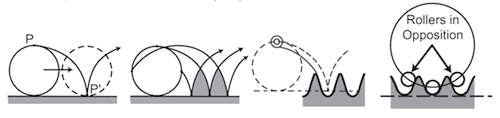

Mikrolar’s engineers found a way to achieve faster, quieter and more precise operation of the ring gear system. They found Nexen’s Roller Pinion Gear (RPG), which replaces the traditional tooth spur gear design with a roller system that functions more smoothly. Instead of creating a slapping motion as gear and pinion teeth interleave, the roller gear system moves in a tangent path and rolls down the tooth face. The rollers meet the ring gear teeth smoothly and evenly, which effectively eliminates backlash, tooth slap, fatigue and noise associated with traditional spur gear and chain drive systems. The RPG’s meshing action provides backlash of less than 3.2 μm (0.00013 in.) and positional accuracy up to ± 30 μm (± 0.00118 in.) which does not suffer from periodic error accumulation.

The ring assembly of the RPG system provides improved repeatability, speed, and accuracy as compared with spur gear systems.

“Some of our customers are interested in very small increments of motion,” said Fortier. “If this is the case, because the RPG features a rolling element […] it is very easy for our robot to start and stop moving more precisely.”

In addition to delivering high precision, the RPG system can support heavy payloads with its load-bearing design. The RPG system offers solid ring gears for any diameter under 750 mm and segments, which can be combined to make ring gears of any size. This creates a solid gear system that is robust enough to support heavy payloads, and flexible enough to allow for the 360 degrees or more of rotation required in many applications of the R-Series robot. The RPG system enables the rotopod to rotate faster than the previous system.

The RPG maintains its precision while working at meshing pitch circle speeds up to 11 m/s (36.1 ft./s).

Nexen’s roller gear system addresses gear tooth slap

As for maintenance, the RPG typically requires lubrication every two million pinion revolutions or every six months. It has life ratings up to 336,000,000 m (1,102,200,000 ft.) of circumferential travel, and features a proprietary surface treatment, providing stainless steel-like corrosion resistance at a lower cost and with less wear.

By switching to the RPG system, Mikrolar has increased the efficiency, accuracy, speed and robustness of their R-Series, making these rotopods an ideal solution for an even broader range of new applications.

Mikrolar, Inc.

www.mikrolar.com

Nexen Group, Inc.

www.nexengroup.com

::Design World::

Filed Under: Factory automation, MECHANICAL POWER TRANSMISSION, Gears • gearheads • speed reducers, Mechatronics

Tell Us What You Think!