West Chicago, IL – R+W, a global brand of precision couplings for motion control and automation systems, has just opened a new US‐based manufacturing facility with expanded machining capabilities and assembly operations for its

West Chicago, IL – R+W, a global brand of precision couplings for motion control and automation systems, has just opened a new US‐based manufacturing facility with expanded machining capabilities and assembly operations for its

precision couplings and line shafts. The company relocated into the 30,000-square-foot facility in West Chicago, IL in late 2022, and is currently ramping up to produce the majority of its precision bellows couplings, elastomer couplings and line shafts for the North American market here.

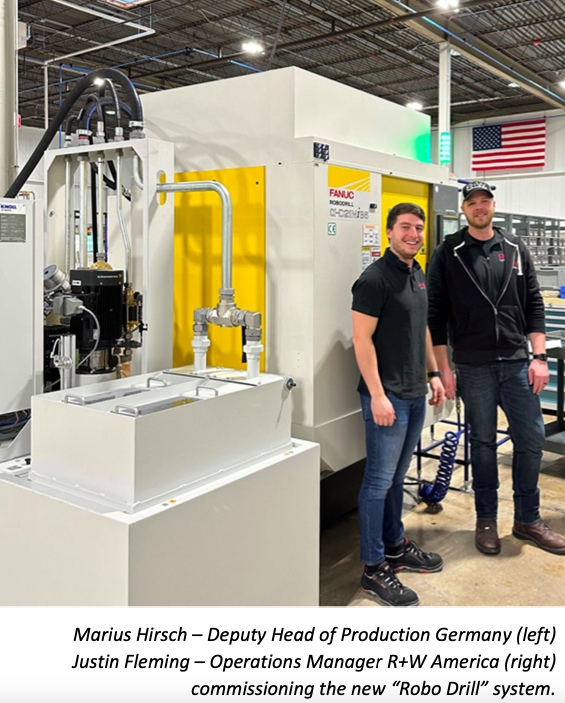

Significant improvements to product availability and lead times are planned, and already partially underway via a major expansion to the depth and variety of elastomer‐jaw coupling hubs being kept on hand. Models EKH, EK7 and EK6 with fully split clamping hubs, expanding shaft hubs, and conical clamping ring hubs respectively are now being delivered within a few days of order entry, just as the classic models EKL and EK2 with clamping hubs have been for the past several years. Many thousands of units with finished bores are ready to be deployed into coupling assemblies, and a new highly automated machining technology, committed to short-run bore diameter modifications of R+W coupling hubs has been installed, reducing the cycle time for machining custom bores and tolerances to a small fraction of what it was before. But this is only the beginning.

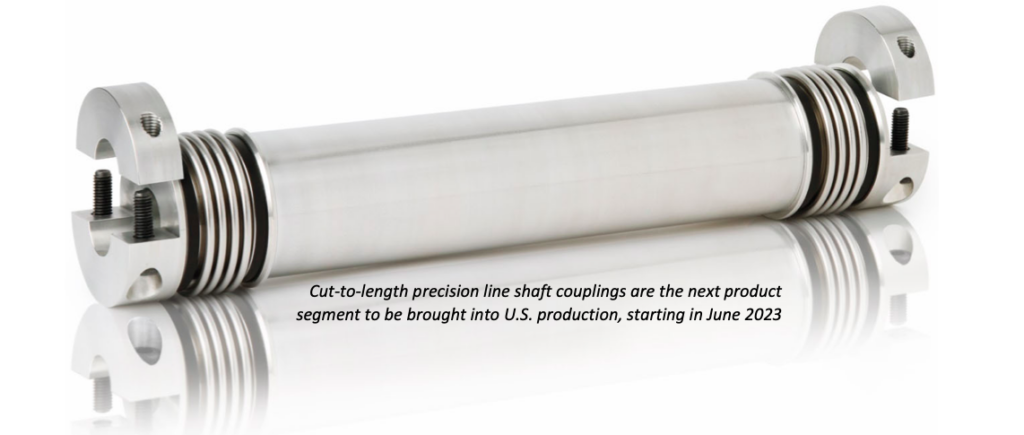

Starting in March the classic bellows coupling model BK2 up to 300 Nm began to be assembled at R+W America in lieu of back-ordering product to be made at the company headquarters in Germany. This has allowed R+W to start delivering orders of up to 10 pcs in 2 weeks or less, without any additional expediting necessary. The best‐selling bellows coupling models MK2 and BKL with clamping hubs are coming fully online in April and are already being assembled locally for rush orders. This represents a vast improvement over previous methods and increases the situations in which orders can be delivered in 24 hours for emergency cases. Similar overall improvements to the standard delivery times for the MK2 and BKL product lines are expected in the immediate future, and line shaft coupling assembly is slated to begin in June of this year.

The North American market and specifically the U.S. market has been regarded as extremely important to R+W since the opening of R+W America in 2001. Over this time the company has gradually built‐up design, distribution, and machining services but stopped short of full bonding assembly operations until now.

The North American market and specifically the U.S. market has been regarded as extremely important to R+W since the opening of R+W America in 2001. Over this time the company has gradually built‐up design, distribution, and machining services but stopped short of full bonding assembly operations until now.

The assembly process for bellows couplings is critical and with a small percentage of opportunities for high-volume production runs. In most cases, the two end hub attachments, usually some form of shaft clamping device, are held together by their bores or centering features on a precision mandrel, while a high strength-bearing retaining compound is used to permanently bond the bellows between them. Assembling in this way helps to guarantee concentricity between the hubs while allowing the bellows to remain in a relaxed state, without any bending or crimping stresses applied to it. This requires a highly flexible production facility and a large variety of tooling. Because of the demanding nature of the applications into which bellows couplings are often deployed, the bonding process also needs to be perfectly controlled. Recent growth in North America experienced by R+W has finally enabled the company to replicate processes performed at the company’s headquarters in Germany on a similar scale.

“Considering the long‐term growth prospects for both manufacturing and automation in North America, and the increasing need for speed and flexibility in the marketplace, this move is a win‐win for both R+W and its customers,” says Dan Skrocki, President and 20‐year veteran of R+W America.

As each individual product group comes online the new precision coupling factory is increasingly unique outside of Europe – especially as far as manufacturing of precision bellows couplings is concerned. Designers of motion systems are under increasing pressure to make things faster, lighter, more compact, and more energy efficient. Precision-manufactured bellows couplings offer advantages in all these areas while performing the basic work of transmitting rotation and relieving bearing loads between drive components. The formed metal bellows is one of the only types of compensation elements found in couplings that is continuously symmetrical. This lends itself to a natural balance and consistency of output rotation that is ideal for smooth running at high speeds in addition to making angular positioning more reliable within a single rotation.

Compared with other types, the bellows are also extremely lightweight. The thin‐walled stainless steel tubes they are made from carry significant torque loads and maintain a very high torsional stiffness while using minimal material. They are routinely mounted to customized drive interfaces to help avoid unnecessary use of shafts and adapters between components, which aids in reducing overall size and inertia. Along with being free of any wear or moving parts, these features amount to their being an increasingly popular tool in mechanical design for demanding applications. Making them more readily available to the engineering community is the next logical step in keeping with this trend.

Filed Under: Coupling Tips