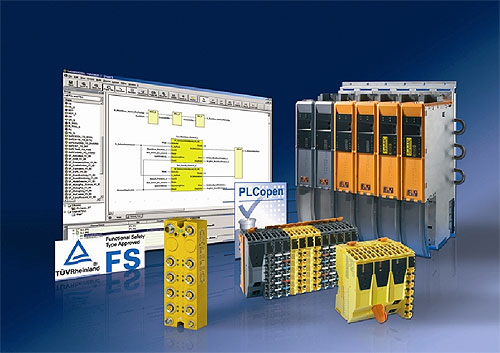

With the SafeDESIGNER development and configuration tool, B&R provides an integrated safety tool for programming safety-related functions from within the Automation Studio development environment. Thanks to complete integration of the safety technology, programming the safety application is reduced to virtual wiring of logical function blocks. Fixed-wired safety circuits are now a thing of the past.

The SafeDESIGNER from B&R supports easy linking of logical library function blocks – in principle, this refers to virtual wiring reproduced using software.

PLCopen and IEC conformity

In addition to function blocks and language elements that conform to IEC 61131-3, users have a library certified by TÜV Rheinland with 20 function blocks for machine automation available to them. All function blocks correspond to the PLCopen standard. Through virtual wiring of the function blocks, the user profits from a clearly structured and well-arranged work method. In this way, errors can be found and prevented very early in all development phases.

The safety application created in SafeDESIGNER is processed in a safe controller – the SafeLOGIC – which supports cycle times starting at 1 ms and connection of up to 100 peripheral devices.

Optimized commissioning times

Transferring the safety signals via Industrial Ethernet clearly reduces setup and service work. In addition, programming in Automation Studio significantly reduces commissioning times.

B&R Automation

www.br-automation.com

::Design World::

Filed Under: Factory automation, CONNECTIVITY • fieldbuses • networks, INDUSTRIAL SAFETY SYSTEMS, PLCs + PACs

Tell Us What You Think!