Innovatively designed safety systems respond to the increasing demand from the food manufacturing and packaging industry for highly effective, failsafe safety measures. “While the food industry is rightfully calling for the highest levels of machine safety, they also seek increased diagnostics and flexible systems that are easy to operate,” said Lloyd Sinnott, business development manager for ABB Jokab Safety.

The Eden line of non-contact safety sensors includes the Adam and Eva; non-contact safety sensors for use on interlocked gates and hatches. The non-magnetic, non-contact closure technology not only delivers high levels of safety, it includes built in diagnostics and quick disconnect features. The maximum sensing distance between Adam and Eva is currently 15 mm ± 2 mm. Up to 30 Eden Safety Sensors can be connected in series and still achieve the same safety level in the safety circuit. It is also possible to connect safety light beams and E-stops in the same safety circuit. The Eden E encapsulated IP67K version is available for even the harshest environments.

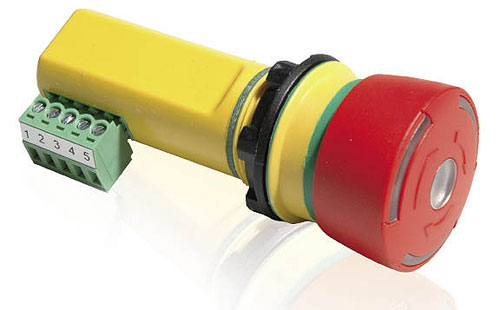

The small modular illuminated emergency stop system, developed to fulfill the need for a small and easy to install E-stop, features built-in diagnostic information in a ready-to-mount package. The size of the device makes it possible to install it wherever needed; and with M12 connections or cable and central mounting holes, the Smile E-stop sensor is easy to install, especially on aluminum extrusions. Other features include quick connect cabling and system status feedback at-a-glance.

Designed with packaging and food processing markets in mind, a new generation of mechanical and magnetic interlock switches offers more flexible mounting and increased ranges. Food grade stainless steel switches are available in many footprints.

And the Pluto is an “all-supervisor” system where inputs and other information are shared via the databus, for a simpler design and high level of safety. The key difference between Pluto and conventional safety PLCs is that there is no “supervisor-subordinate” relationship between the units connected to the safety bus. Each Pluto is a “supervisor” unit and can see the other Pluto’s inputs and outputs, thereby able to make decisions about its own safety environment. Several safety sensors can be connected to one input while still achieving the upmost safety. The flexible scalable modular design allows the system designer many options when creating the blueprint for the safety system.

ABB

www.abb.com

Filed Under: INDUSTRIAL SAFETY SYSTEMS, MORE INDUSTRIES

Tell Us What You Think!