This webinar was presented on Wednesday June 24, 2020

Please click below to watch on demand

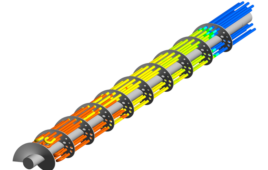

When torque overloads occur in systems, critical components fail and costly unscheduled downtime ensues. Torque overloads can occur in almost any application you may face, and many installations do not have any form of overload protection when installed. Learn how to solve your torque overload issue using an overload protection device. The most common and cost effective method is to use a friction disk style torque limiting device. The introduction of the Tsubaki Torque Limiter Sprocket helps make protecting your equipment even easier. The new Torque Limiter Sprocket has all of the essential protection of a friction disk torque limiter, but in an easy to use, factory preassembled package. The Torque Limiter provides torque overload protection to protect critical equipment from failure; and now, with a pre-assembled package, just set the torque and install to the shaft, and the Torque Limiter Sprocket is ready to protect critical equipment.

Attendees of this webinar will learn:

- How to select which form of overload protection to use.

- When is a friction disk torque limiting device right for my application?

- How can Tsubaki’s Torque Limiter Sprocket save you time and money?

Featured Speakers:

Bryan Brickey

Product Specialist – Power Transmission Components

US Tsubaki

Derek Glugosh

Derek Glugosh

Product Manager – Sprockets

US Tsubaki

Lisa Eitel

Executive Editor, Moderator

Design World

Filed Under: WEBINARS