When selecting the right supplier for semiconductor test handling equipment, it is important to scrutinize suppliers before taking on a design, according to Delta Design senior mechanical engineer Craig Gadd. When the company opted to develop its Matrix test handler in-house, it partnered with Intech Corp. because the supplier demonstrated an intricate understanding of its products and how they are applied

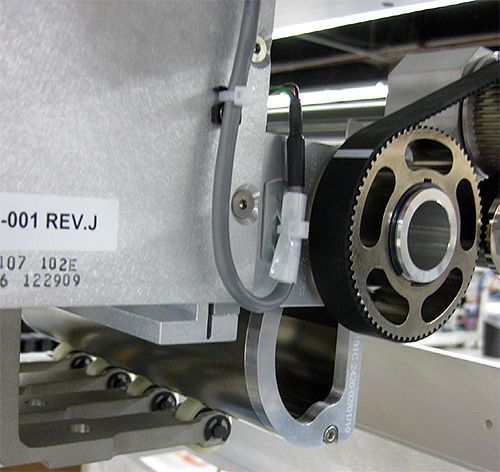

The close-up of the handler mechanism shows the cam followers mounted in a row along the bottom of the photograph.

Delta approached Intech with a request to provide a cam follower assembly that would operate 100 in./s, with intermittent static loads of 50 lb, and last for a minimum of 10 million revolutions in a 50° C ambient temperature. In addition, the most important consideration for the follower was that it would not require lubrication or maintenance over its appointed lifespan.

Intech produced calculations specific for the follower and how it was to be used on the Matrix machine. “From that data, I understood that they had a good theoretical understanding of their components’ capabilities,” said Gadd. “Plus, Intech took each component of our requirements into consideration separately.” Follow-up discussions included the specifics on the grease to be used and a potential modification to the press fit of the tire to the bearing assembly.

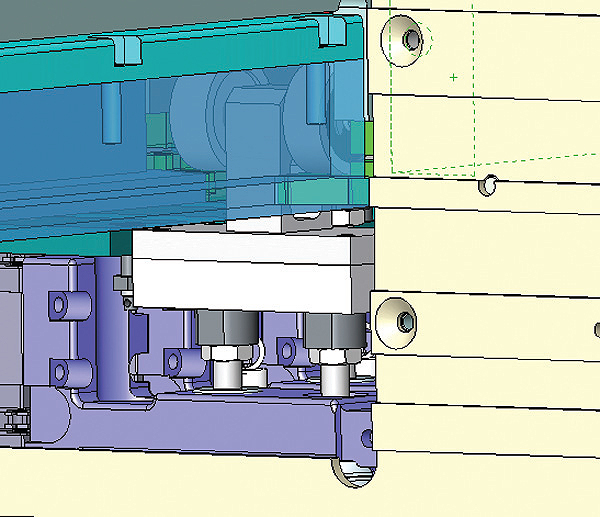

The Matrix test handler was designed with eight heads in all. It uses 24 cam followers per machine. Two of the followers ride on the upper track, while one rides against the cam itself.

Delta Design reports that the development of the Matrix test handler increased productivity by up three times, improved higher parallelism by four times, and increased active thermal control per test site. In addition, the Intech Power-Core cam follower helped reduce overall noise, vibration, and harshness.

In this CAD screen shot, the two rollers that ride on the upper track can be seen through the muted area.

The roller in the application runs across a track that has an expansion joint built into it. The specially created Power-Core nylon tire on the roller also helped reduce the alignment precision needed in the expansion joint. Off-the-shelf cam followers in the size that Delta required for the application were not sealed, only “shielded.” Sealing helps to extend the life of the roller because contaminants are kept to a minimum.

Delta Design

www.deltad.com

InTech Corp.

www.intechpower.com

::Design World::

Filed Under: Semiconductor manufacture, TEST & MEASUREMENT

Tell Us What You Think!