The manually actuated SCHUNK KONTEC KSC clamping vises are efficient all-rounders for raw and finished part machining. They combine high clamping forces, convenient operation, and short set-up times, and are cost-effective. Particularly for use in automated machine loading, SCHUNK further expands its standard program with the affordable SCHUNK KONTEC KSC-F single-acting clamping vises with a fixed jaw. It has quick adjustment of the clamping range, flat design and a low weight — excellent conditions for an unmanned workpiece handling on pallet systems. The three sizes KSC-F 80, KSC-F 125, KSC-F 160 are particularly designed for the common pallet sizes 320 x 320 mm, 400 x 400 mm, and 500 x 500 mm. Due to the 160° quick clamping, workpieces are clamped with a torque wrench in a second, and the vise is safely locked. Due to clamping by tension, the bending load at the base body is minimized, making the vises suitable for the use on a SCHUNK VERO-S quick-change pallet system. With reversible jaws, the vise covers enormous clamping ranges between 0 to 192 mm, 0 to 308 mm or 0 to 434 mm, depending on the unit size.

The manually actuated SCHUNK KONTEC KSC clamping vises are efficient all-rounders for raw and finished part machining. They combine high clamping forces, convenient operation, and short set-up times, and are cost-effective. Particularly for use in automated machine loading, SCHUNK further expands its standard program with the affordable SCHUNK KONTEC KSC-F single-acting clamping vises with a fixed jaw. It has quick adjustment of the clamping range, flat design and a low weight — excellent conditions for an unmanned workpiece handling on pallet systems. The three sizes KSC-F 80, KSC-F 125, KSC-F 160 are particularly designed for the common pallet sizes 320 x 320 mm, 400 x 400 mm, and 500 x 500 mm. Due to the 160° quick clamping, workpieces are clamped with a torque wrench in a second, and the vise is safely locked. Due to clamping by tension, the bending load at the base body is minimized, making the vises suitable for the use on a SCHUNK VERO-S quick-change pallet system. With reversible jaws, the vise covers enormous clamping ranges between 0 to 192 mm, 0 to 308 mm or 0 to 434 mm, depending on the unit size.

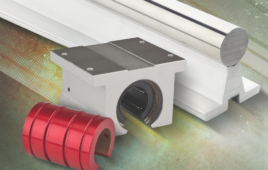

Centric clamping vises with encapsulated drive

But SCHUNK also expands the range of centric clamping vises and upgrades the program with larger vises. In addition to the sizes 80 and 125, this all-rounder will be available in size 160 with a base body length 280 mm, and high clamping forces of up to 50 kN. A preloaded precision ball bearing mounted, backlash-free spindle ensures an excellent repeat accuracy of +/- 0,015 mm, and allow precise machining of the first two sides in one clamping system. The completely encapsulated drive and the integrated chip removal ensure for a particularly high process stability and minimum wear. With the jaw quick-change system it is possible to exchange the workpiece-specific jaws in just a few steps and cover a broad workpiece spectrum.

Wide selection of chuck jaws

The new KONTEC KSC and KSC-F clamping vises seamlessly fit into the SCHUNK modular system for highly efficient workpiece clamping. Clamping pins of the VERO-S quick-change pallet system can be directly mounted into the base body of the vise. Combined with the quick-change pallet system, they can be quickly exchanged on the machine table and at maximum repeat accuracy. The vises can be quickly equipped with different jaws from the SCHUNK standard chuck jaw program for stationary workholding, which generates a high degree of flexibility.

Schunk

schunk.com

Filed Under: Bearings, Clamps