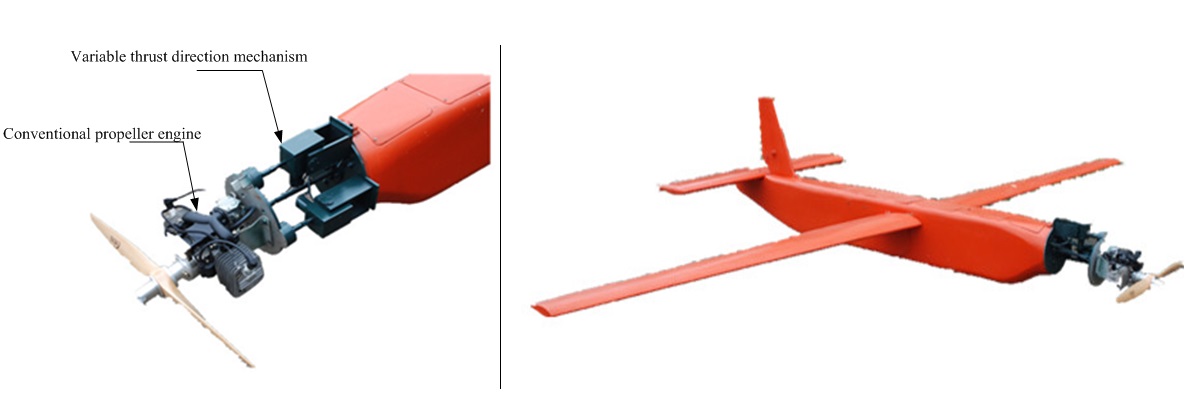

The proposed variable thrust direction mechanism is shown in Fig.1, a conventional propeller engine is mounted on a two dimensional rotate disk, which is driven by two servo actuators. By combining the linear motions of the actuator, both the azimuth and the altitude angle of the disk with respect to the fuselage can be controlled, and thus changing the thrust direction of the propeller. (Credit: Science China Press)

The unmanned aerial vehicles (UAV) designed for plateau missions are usually installed with high span chord ratio wings, which provide more lifting force at a relatively low airspeed. Such UAVs, however, tend to lose their maneuverability. Hence, they usually need a larger turning radius and are unable to maintain altitude during sharp slope turning, as the lifting force produced by the wings decreases dramatically when the bank angle is large. This may pose a risk to flight safety in plateau mountain regions. Variable thrust direction (VTD) technology is a type of thrust vectoring control (TVC) that allows a UAV to manipulate the directions of thrust to the fuselage of the aircraft.

Most of the existing designs are for jet engines, and cannot be applied to the conventional propeller engine aircraft. In a paper published in Science China Information Sciences recently, researchers reported a novel VTD mechanism for the conventional propeller engine UAV, which redirects a portion of the thrust from the propeller engine in directions other than the normal axial direction. A combination flight controller for the VTD-enhanced UAV is then proposed to coordinate the VTD-controlled forces and aerodynamic surfaces forces.

The proposed variable thrust direction mechanism is shown in Fig.1. A conventional propeller engine is mounted on a two-dimensional rotator disk, which is driven by two servo actuators. By combining the linear motions of the actuator, both the azimuth and the altitude angle of the disk with respect to the fuselage can be controlled, thus changing the thrust direction of the propeller.

The introduction of the VTD capability to the conventional propeller UAV greatly enhances the maneuverability of the UAV, since the VTD engine enables direct force control of the aircraft. The newly developed VTD UAV was used in plateau missions, demonstrating the usefulness of the proposed technique.

Filed Under: M2M (machine to machine)