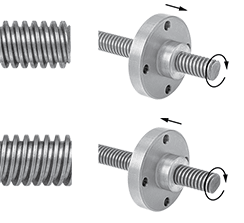

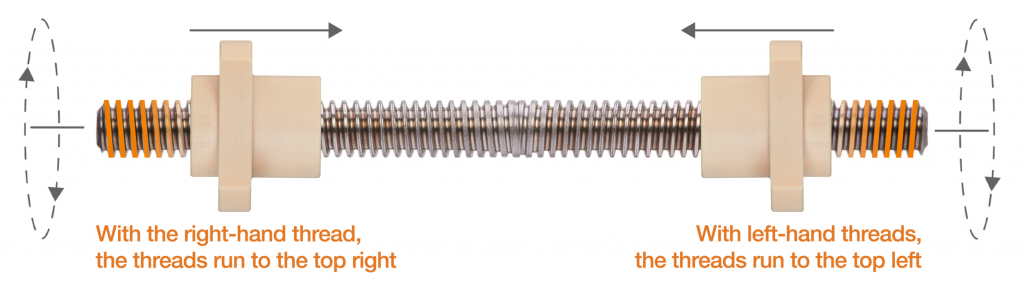

Just like people, ball and lead screws can be either right-handed or left-handed. But in screw terminology, handedness indicates the direction in which the nut moves relative to the direction of the screw’s rotation. By far the most common version is the right-handed screw, in which the nut moves toward you when the screw is rotated clockwise. But left-handed versions, in which the nut moves away from you when the screw is rotated clockwise, are also available — and useful in some applications.

With a left-handed screw, the nut moves away from you when the screw is rotated clockwise.

Image credit: McMaster-Carr

The prevalence of right-handed power transmission screws follows from the domination of right-handed fastening screws. Fastening screws are thought to have been developed with right-handed threads — which tighten when turned clockwise — because most people are right-handed, so their right hand supinates clockwise, allowing them to apply more torque (to tighten the fastener) in this direction.

To demonstrate supination and its relationship to tightening, start with your right hand in a loose fist, like you’re grasping something, with the back of your hand facing up and your thumb on the left side. Then turn your hand to the right so that the palm side is facing up and your thumb is on the right. This is supination of your right hand, and the direction for tightening a conventional, right-handed fastening screw.

Image credit: Accu Ltd.

The availability of left-handed ball screws is relatively limited, although most manufacturers offer a few sizes and designs in both left- and right-handed versions. Lead screws, on the other hand, are commonly available in a variety of designs and sizes with both left- and right-hand options. There’s no performance difference between left- and right-handed screws — the screw’s handedness only affects the nut’s direction of travel when the screw is turned in either direction. But it’s important to note that you can’t use a left-handed nut on a right-handed screw, or vice-versa.

So why would you use a left-handed lead or ball screw when you can use a conventional right-handed screw and just reverse the direction of rotation of the motor? One common reason is to drive two screws from one motor — often via a gear or other transmission component with dual output shafts.

Image credit: igus

Some manufacturers even produce combination left- and right-handed screws, in which a single screw shaft has been machined with left-handed threads on one end and right-handed threads on the other end. Thus, when a motor drives the screw in one direction, the two nuts move toward each other. And when the motor reverses direction, the nuts move away from each other. This design is especially useful in dual-motion linear actuators.

Image credit: THK

Filed Under: Linear Motion Tips