The next-generation of pharmacy automatic pill dispensing systems from Parata® Systems delivers pills quickly and efficiently. But these systems might not operate so well if it were not for a specially designed spring coupler that prevents pressure changes in the compressor. The Parata Max™ holds and automatically dispenses up to 232 finished prescriptions, more than the 196 average prescription volume at U.S. pharmacists. An earlier design caused the system’s compressor to overwork, sharply reducing counting speed.

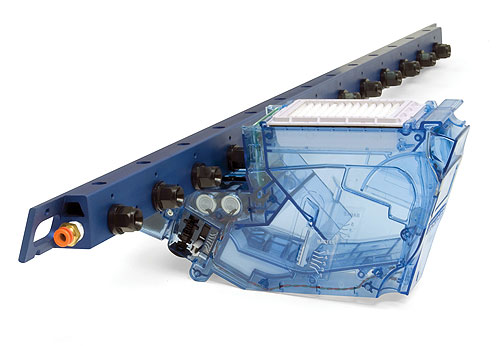

Seal-coupler from MR&P reliably connects components in the pneumatic motion system of Parata’s Max and Mini automated pill dispensing system for pharmacies. The seal-coupler (new design left) replaces an earlier design (right). The seal coupler connects to pill dispensing cells (below) also manufactured by MR&P.

The Max system automates 60% of an average pharmacy’s total prescription volume with upkeep of less than an hour a day. The system does not make drug or dose errors, the source of 88% of medication errors, and delivers counting accuracy 10 times higher than the industry standard. Also important, the system is compact, occupying just 12 square feet, so it replaces a single shelving unit in most pharmacies. The Parata Mini is an entry-level automation system.

Minnesota Rubber and Plastics (MR&P) was consulted to develop a new seal-coupler design as well as other related components used in the system.

In the pneumatically actuated system, the seal-coupler is a critical intermediary device. Positive sealing is imperative so no pressure changes occur that could affect compressor function, airflow rate, and ultimately pill count speed and accuracy.

When activated, regulated pneumatic pressure moves the pills from individual cells that both store and dispense. These are “smart cells” with an electronic circuit board that broadcasts the cell’s location on the system, so the robot always selects the correct cell for dispensing.

The seal-coupler is a spring-loaded device with a molded lip-seal that locks connections together in the pneumatically driven motion system.

The new seal-coupler is a spring-loaded assembly with an upper and lower housing molded from a nylon material that is ultrasonically welded together. Within this housing, a spring is centered on a retainer at one end and a poppet core on the other end. This poppet core, under tension from the spring, locks into a special lip seal molded from a durable, proprietary elastomer material.

The lip seal design addressed the initial problem of seal alignment with a more precise-fitting lip configuration at the seal end. The elastomer material improved wear resistance with a leak-proof connection to the high-pressure system.

The overall manifold’s profiles were designed and fabricated to strict specifications so that the manifold ports sealed and connected properly. Similar improvements and efficiencies were brought to several other components including vial descrambler fingers and cradle assemblies.

Parata Systems

www.parata.com

Minnesota Rubber and Plastics

www.mnrubber.com

::Design World::

Filed Under: Assembly, Medical-device manufacture, Materials • advanced

Tell Us What You Think!