Whether pushing to develop a “million mile” seal for power generation applications or a 20,000-hour solution for industrial gear box use, Freudenberg-NOK Sealing Technologies Simrit systems engineers and technology managers are on the forefront of solving today’s most pressing industry challenges.

The global supplier’s proven technology, such as CASCO – a unique engine sealing solution that works in a plane parallel to the rotating shaft – or its technology-leading Simmerring™ – a staple for sealing the shaft of industrial gear boxes with low-friction/ wear-resistant materials and low friction designs – the goal is always to minimize customer down time and provide a more reliable solution.

Freudenberg-NOK is showcasing its next generation of seals, its Levitex products, at the 2014 International Fluid Power, Power Transmission, Motion Control Exposition in Las Vegas. Levitex is the first nearly friction-free crankshaft seal produced by Freudenberg-NOK.

“Earth-moving and heavy construction equipment require robust mechanical systems that provide high sealing performance under the most arduous working conditions, as well as are immune to natural contaminants like salt, sand and harsh weather, and difficult operating conditions, such as axial clearance, radial unbalance and oil aging,” said Joel Johnson, senior segment director, Mobile Machinery, Freudenberg-NOK.

“These seals offer our customers a real value proposition,” Johnson continued. “We’re dedicated to developing and providing sealing components and systems that withstand a variety of the harshest environments. Our portfolio of power generation and power transmission sealing

technologies has been developed and tested to keep our customers’ equipment profitable no matter what conditions they’re operating under.”

On display at IFPE are key sealing products and technologies for Freudenberg-NOK Simrit’s power transmission and power generation customers, including:

- Position Sensing Encoders for Rotational Applications – utilize a proprietary formulation of ferrite loaded polymer molded in a desired geometric shape and magnetized to a specified pole pair configuration;

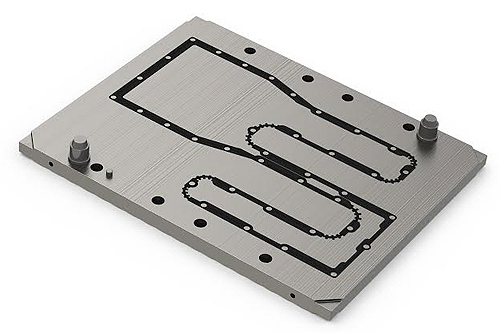

- Deformed Large Gaskets – oversized gaskets which are specially designed to be molded in standard-sized platens using patent-pending gasket geometries;

- Levitex – a cost-optimized, dry gas seal, is the first nearly friction-free crankshaft seal;

- Curve Gasket – unique gasket design enabling customers to achieve reliable sealing while using less material in their components, reducing both cost and weight;

- Gas Lip Valve Stem Seal – protects the main lip from blow-by and carbon build-up, which results in increased durability and reduced emissions;

- CASCO Self-contained Seal Design – developed specifically to extend seal life while solving difficult operating conditions, including dynamic end play and radial run-out; in many cases it does this while reducing overall seal system costs; also lowers friction torque and power loss;

- Plug & Seals – elastomeric-coated pipe sections that create a safe, leak-free connection between housings with an adaptable version made of Polytetrafluoroethylene for high temperature applications;

- Accumulators – offering exceptional functional reliability and durability, and open up versatile application areas with operating pressures up to 350 bar;

- Linear Compensators – compact design with reliable performance for today’s suspension systems; and

- Track Roller (Floating) Seals – offer strong seal performance, excellent contamination resistance, longer intervals between services, and lower labor and maintenance costs.

Deformed Large Gaskets – oversized gaskets which are specially designed to be molded in standard-sized platens using patent-pending gasket geometries

Levitex – a cost-optimized, dry gas seal, is the first nearly friction-free crankshaft seal

Freudenberg-NOK

www.fnst.com

Filed Under: Seals • O rings, MOTION CONTROL, Seals

Tell Us What You Think!