Self-tapping screws are the most common type of mechanical fasteners for assembling all sorts of products. They cut or form a thread as they are inserted, which eliminates the need for molding an internal thread or a separate tapping operation. Self-tapping screws are a particularly economical means for joining plastics and dissimilar materials, and the parts can be disassembled and reassembled easily without any danger of damage.

Self-tapping screws come in two basic types; thread forming and thread cutting. Thread-forming screws deform the plastic material and leave behind an intimate thread shape. By comparison, thread-cutting screws physically remove material to form the thread. To determine which one is better, you need to know the plastic part characteristics including its maximum flexural modulus. For instance, when the maximum value is less than 1500 MPa, thread-forming screws are fine because the material can be deformed without involving high hoop stress.

When the flexural modulus is between 1500 and 3000 MPa however, the proper type of self-tapping screw to use is not easy to determine. In general, the stress generated by a thread-forming screw is too high for certain resins, and thread-cutting screws should be used unless repeated disassembly is necessary. However, plastics such as Zytel nylon resin and Delrin acetal resin work well with thread-forming screws.

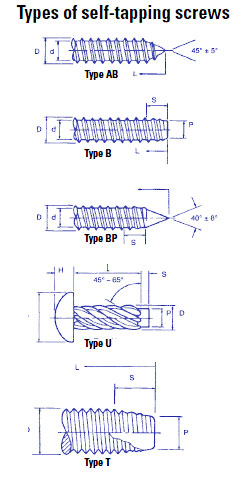

Thread-forming screws come in five designations: Type AB, B, C, BP and U, which define a specific thread design. AB and B are fast driving, space-thread screws. The BP screw is much the same as the B screw except that it has a 45° included angle and unthreaded cone points. The cone point is useful in aligning mating holes during assembly.

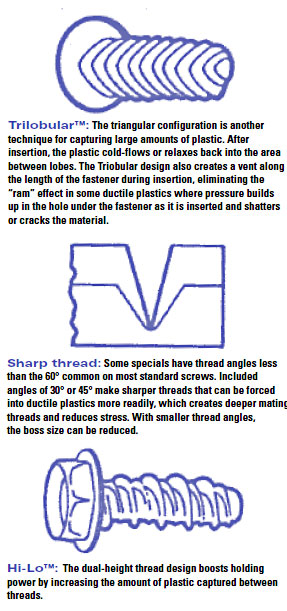

The U blunt-point type is a multiple-thread drive screw for permanent fastening. The U-type screw is not recommended for screw removal scenarios. For those instances, special thread forming screws such as the Trilobular™, which are designed to reduce radial pressure, can be used. Screws with non-circular cross sections have slightly higher driving and stripping torques.

Special types

The HI-Lo™ fastener is another unique thread form. It has a double-lead thread where one thread is higher than the other. Its sharp 30° included thread angle allows for a deeper cut into the material and reduces the hoop stress that would be generated by a conventional 60° thread-angle form. In addition, the Hi-Lo screw has a smaller minor diameter than a conventional screw.

The shape increases the material in contact with the high flat thread and increases the axial shear area. All of this contributes to a greater resistance to pull out and a stronger fastener. This type of screw can be either thread forming or thread cutting with the thread cutting variety used in most materials with higher absolute values.

Thread-cutting screws are used for materials or resins with flex modulus values in the 3000 to more than 7000 MPa range. They come in type designations of T, D, F, BT, and BF. The resins in the 3000 to 7000 MPa category are the 13% glass-reinforced Zytel nylon resin materials and Minlon mineral-reinforced materials. In these more rigid materials, thread-cutting screws provide high thread engagement, high clamp loads, and do not induce high residual stress that could cause the product to fail after they are inserted.

Plastic materials with flexural modulus values above 7000 MPa are usually brittle and tend to granulate between the threads and cause the fastener to pull out at lower than predicted force values. Resins in this category are typically 33% and 43% glass-reinforced Zytel nylon resins, Rynite PET-reinforced polyester terephthalate resin, Crastin PBT-reinforced polybutyl terephthalate resin, and DuPont high performance polyamide resin Zytel HTN.

For these materials, the finer threads of the Type T screw are recommended. Even with the fine pitch screws, backing out the screw will shear most of the threads in the plastic and prevent the same sized screw from being used again. When fasteners must be removed and replaced often, metal inserts should be used for this group of materials, or the boss diameter should be made sufficiently large to accommodate the next larger diameter screw. Larger screws can be used for repairs and provide greater clamp loads than the original installation.

Metal inserts come in five types: Ultrasonic, heated, molded-in, expansion, and solid bushings. The inserts are held in place by knurls, grooves, and slots, which are designed to resist axial and angular movement. The ultrasonic insert is pressed into the plastic, which melts under high frequency ultrasonic vibrations, and the insert remains secure when the plastic solidifies. Another technique uses inserts heated from 30° to 50°C above the plastic’s processing melt temperature and the insert is pressed into a slightly too small hole. Molded-in inserts are placed in the mold and are designed to reduce stress after cooling. Expansion inserts are slipped into the hole and do not lock in place until the screw is inserted, which expands the insert wall. Solid bushings are usually two-piece inserts. The body screws into a prepared hole, and a ring locks the insert in place.

::Design World::

Filed Under: Screws • nuts • bolts, FASTENING • JOINING • locks • latches • pins

Tell Us What You Think!