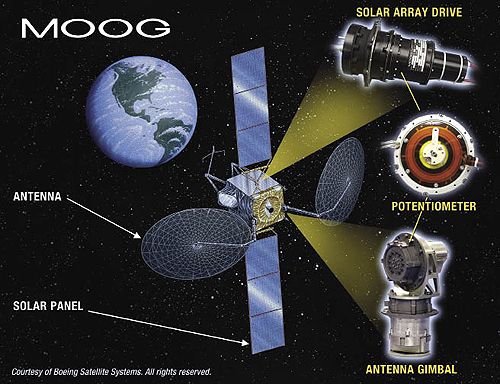

Both rotary and linear conductive plastic potentiometers have been used widely in space-flight applications. These devices offer simple analog position, as well as low power and temperature compensation data. However, due to the sliding contact nature of the devices, they have limited life and are prone to noise and drop-outs in signals after a few thousand revolutions, caused by debris and polymer formation.

A detailed study was conducted for alternative position encoding technologies that would address the finite life and signal integrity issues. It concluded that all alternative technologies would require onboard and external electronics. That’s an expensive proposition, as most satellite manufacturers have proven heritage electronic systems, so any change would require a redesign and re-qualification.

Since the noise and drop-outs are a direct artifact of wear, a membrane potentiometer technology was chosen; it offers all the features of the conventional potentiometers with the added benefit of a rolling contact for longer life and noise-free operation. Products and specifications of several manufacturers of these type devices were tested and studied.

The overall project goal was to design and specify a membrane potentiometer, tailored to the specific needs of spaceflight use. The product needed to meet or exceed the performance specifications of conventional conductive plastic potentiometers currently used on Moog actuators.

At a minimum the product had to:

• operate in a vacuum

• operate for more than 100,000 revolutions without creating the slightest noise

• deliver 360° bi-directional mechanical travel

• deliver electrical travel of 340° minimum, 360° max.

• have a total resistance of 10,000 Ohms ±10%

• have insulation resistance of 100 MOhm min. at 100 V dc between all wires

• deliver absolute linearity of ±0.25%

• have an output smoothness of 0.035% or better

• have a voltage gradient of 2.5 mV/degree min. with 1.0 V applied

• operate for more than 100,000 revolutions

• survive temperatures when non-operating of -75° to 120° C; when operating of -50 to 110° C

• have a shelf life of 10 years

• use applied voltage of 2.25-10 V dc

• have an operating wiper speed of from 0 to 25 rpm

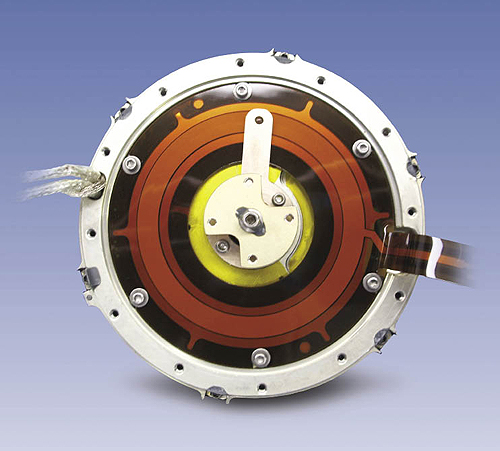

Hoffman and Krippner’s SENSOFOIL Hybrid technology was selected to replace the current potentiometers. Development testing at Moog started using the H&K rotary potentiometer with their existing commercial materials and manufacturing processes. The new product would be called the QuieSense potentiometer. All the materials and processes used in the construction of the QuieSense potentiometer were carefully selected to meet the space flight outgassing requirements of TML <1% and CVCM <0.1%. Sample of every material was sent to an independent chemical laboratory for testing.

Currently the unit is being subjected to extended life testing, installed on a Moog standard Type3 rotary actuator. This test will extend until the motor input shaft accumulates more than one million revolutions.

The extended life testing will expose the two QuieSense qualification potentiometers; one potentiometer referred to as fine attached directly on the stepper motor rotor shaft, and the other referred to as coarse coupled to the actuator output shaft. The test units will be exposed to various predetermined environments enveloping most spaceflight requirements.

Standard SENSOFOIL potentiometers can achieve an absolute linearity of around 1%. QuieSense noise-free potentiometers are trimmed to achieve a linearity of better than 0.25%. The worst linearity achieved during qualification testing was 0.212% at cold. Since the wiper slides on the external Kapton surface, any wear does not affect the performance characteristics of the potentiometer. Tests conducted with several wiper contact materials demonstrated that although POM is an excellent choice for commercial use; due to its limited high temperature performance, Vespel is a better choice for space-flight environment.

Moog

www.moog.com

Hoffman and Krippner

www.hoffmann-krippner.com

Filed Under: Aerospace + defense, Potentiometers, SENSORS, TEST & MEASUREMENT

Tell Us What You Think!