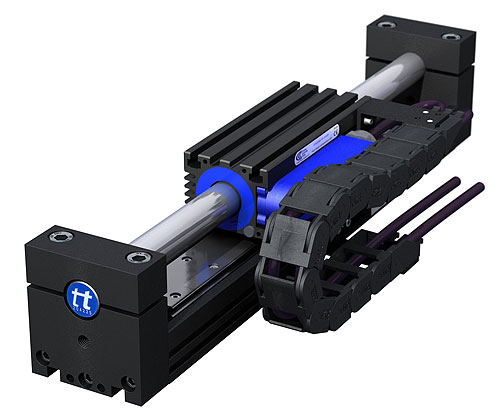

Copley Controls releases its new Servotube Module for linear drive actuation in pick and place gantry and general materials handling applications. The new Servotube direct drive tubular linear motor module is a cost-effective solution for high speed, flexible applications, replacing the need for belt drive or ball screw systems. In typical configurations, the Servotube Module is 10 times faster than traditional ball screw systems, with higher reliability.

The Servotube Module has built-in position feedback – eliminating the need for a linear encoder in many applications. Supported by an integral bearing rail, the non-contact drive system delivers life expectancy far exceeding belt and ball screw systems. The Servotube Module is ideal for OEM applications requiring easy integration. The load is mounted directly to the rugged forcer. Several modules may be integrated together to create multi-axis systems with minimal design effort.

The internal feedback device of the Servotube module provides 12 micron repeatability and 350 micron absolute accuracy. For applications requiring higher degrees of accuracy, the Servotube Module can be configured with a 1 micron linear encoder.

The Servotube module is available in four models delivering a continuous force of 6 to 19.3 N (1.35 – 4.3lb) with peak forces up to 92 N (20.7 lb). Maximum velocity can be 10.8 m/s depending on move distance. Standard stroke lengths up to 825 mm are available. Servotube is complemented by a range of matched, self tuning amplifiers and indexers with complete plug and play capability.

Filed Under: Encoders • linear, Material handling • converting, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!