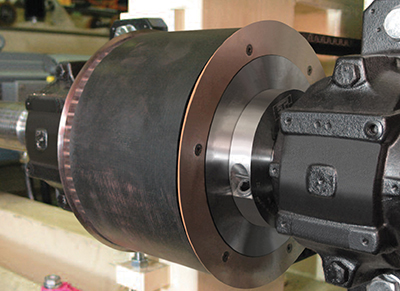

Zero-Max’s ETP Power keyless connections are a suitable locking device in laminated floor manufacturing systems. They are also an excellent choice for locking into position gears, pulleys, sprockets and other components in automated machinery.

Zero-Max’s ETP Power keyless connections are a suitable locking device in laminated floor manufacturing systems. They are also an excellent choice for locking into position gears, pulleys, sprockets and other components in automated machinery.

Handling torque ranges from 531 to 10,620 inch lbs. (60-1200 Nm), these ETP Power shaft locking bushings from Zero-Max provide the highest radial load performance within the single screw ETP product line.

The ETP Power single radial screw design ensures fast mounting, repositioning and phasing of the components to the shafts. ETP Power positions in seconds and can be readjusted hundreds of times just as quickly and without any axial movement of the bushing or component along the keyless shaft. An Allen wrench is all that is required to mount and lock these bushings into place. They have sealed, clean lines that resist debris collection and clean easily without any special maintenance.

The ETP Power’s single radial tightening screw provides a solid and more precise connection between shaft and hub unlike conventional shaft locking bushings. It incorporates a double-walled sleeve filled with a pressure medium. When the actuation screw is tightened, the hydraulic pressure medium in the sleeve expands the double walled sleeve, forming a very tight, continuous connection between the shaft and mounted component. The bushing aligns precisely without axial movement as it is tightened.

The unique, single adjusting screw design makes the ETP Power superior to conventional mechanical locking bushings where numerous adjusting screws are needed. Tightening numerous screws creates axial movement of the bushing and is less precise.

Available in 15, 19, 20, 22, 24, 25, 28, 30, 32, 35, 38, 40 mm and ¾”, 1”, 1 ¼” 1 ½” and 1 ¾” shaft sizes. ETP Power bushings are a great choice for new and retrofit applications particularly in automated machinery applications.

Zero-Max

www.zero-max.com

Filed Under: Collars • locking devices, Motion Control Tips

Tell Us What You Think!