Now, one new actuator uses bundles of SMA wire made of specialty nickel-titanium alloy for reliable linear motion.

Dean Pick, P.Eng. • President | Kinitics Automation

Shape-memory alloys (SMAs) are those materials that respond to temperature changes by changing form factor. Originally funded by the U.S. Navy, SMA technologies were first commercialized by Raychem Corp. (now of TE Connectivity) during the 1950s. But the unpredictable nature of early material versions proved a challenge. So over the decades, manufacturers investigated ways (with mixed success) to boost the durability, consistency, and applicability of SMA-based designs.

Force and stroke ratings can be used to select the appropriate Kinitics Automation actuator model, and design engineers can configure the actuators to work with myriad power sources to tailor the response time to the application (and for compatibility with existing infrastructure).

Now one new SMA-based linear-motion offering uses advanced SMA material for repeatable and predictable motion. The manufacturer bundles wires made of SMA and anchors them to an actuator housing. Current through the (electrically resistive) SMA generates this heat; when warmed past a transition temperature, the wires’ atoms realign to another crystalline structure. This results in wire contraction when heated and re-extension when cooled — which in turn makes for linear motion output.

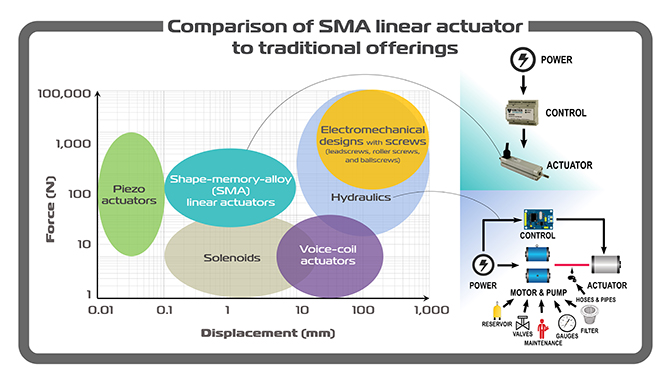

Kinitics Automation actuators use a nickel-titanium shape memory alloy (the NiTi in Kinitics) in a bundled-wire arrangement. The actuators satisfy certain applications better than other linear-motion technologies. On the right, notice how much simpler Kinitics Automation actuator setups are than comparable hydraulic systems.

In fact, this reversible behavior makes SMA-wire-based actuators suitable for an array of motion applications — including those on high-cycling machine axes. The rod is the sole moving part, so the actuator exhibits zero backlash or mechanical slop — regardless of how many times it’s cycled. Research and testing have yielded quantitative industry-standard information about the linear actuators to allow application to real-world motion designs.

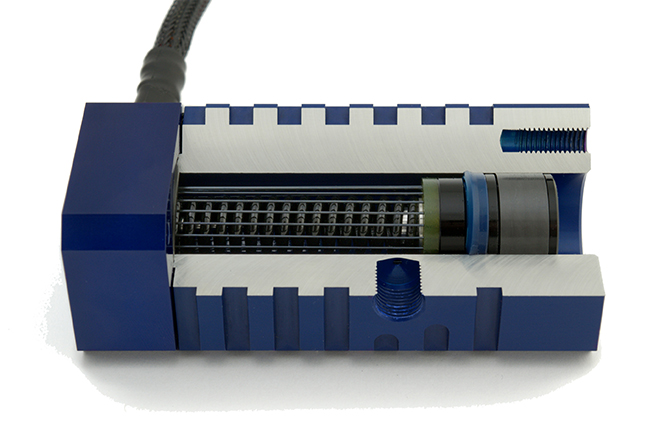

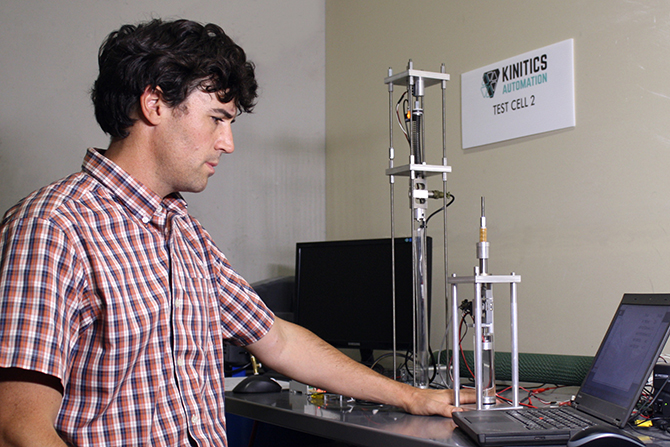

Kinitics Automation Bundled Wire connects several SMA wires to a piston inside the actuator. The wire arrangement’s direct connection between the cylinder body and rod ensure strength and durability. Upon application of electricity (heat), the wires shorten and move the actuator rod. For quality control and MTBF testing, Kinitics Automation runs a laboratory that includes several wire dynamometers that have logged more than 2 million cycles on single pieces of SMA wire.

Kinitics Automation Bundled Wire is a proprietary technology of assembling and connecting shape memory alloy (SMA) wires in a dense array. Bundled Wire technology gives Kinitics Automation SMA linear actuators a high strength-to-size ratio. Plus it retains high wire surface area to allow for forward-stroke times in just 200 msec (or less) and full cycles in less than 5 seconds. When connected to a piston pump as shown here, the technology can be applied to fluid-power applications.

Here’s how an SMA linear actuator works over a linear-stroke cycle:

1. During an initial stroke phase, the bundled-wire SMA linear actuator uses electric power to move a piston towards a fixed end. The amount of power applied dictates piston speed.

2. Next, during an optional hold phase, the piston can hold position for a set amount of time.

3. Then during the return phase, the bundled-wire SMA linear actuator uses heat transfer and force biasing to return the piston to the home position. The rate of cooling and amount of biasing force dictate piston speed.

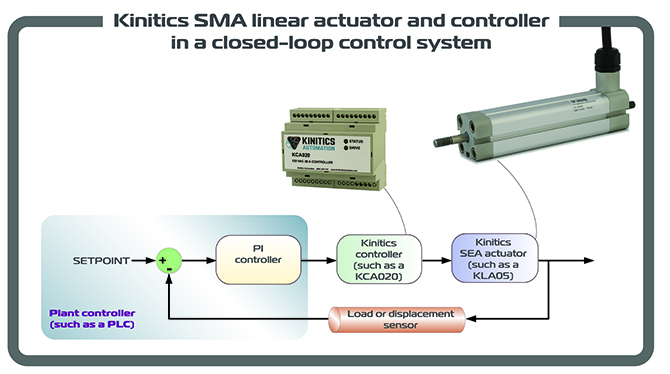

For design engineers developing machine axes requiring positioning or force control, the Kinitics Automation linear actuator is one new option. When paired with a Kinitics controller (such as the KCA020) an analog controller input signal can modulate the actuator gain. Alternatively, the Kinitics controller can also accept a pulse-width-modulation (PWM) signal to dynamically drive the actuator. Combining a Kinitics actuator and controller with a feedback sensor and plant controller yields a closed-loop motion system. Programmers can leverage the actuator’s linear responsiveness when developing their control strategy. Usually it’s possible to use a PI function block — and eliminate the need to develop complex high-order programs.

By adding feedback sensors and a controller to the design, design engineers can even get bundled-wire SMA linear actuators to output complex motion profiles … and fine positioning and force control. For the latter, a specialized drive-controller regulates current input to control output precise linear motion.

Though beyond the scope of this article, variations on the bundled-wire SMA arrangement for piston-pump operation can deliver fine pressure control, discharge temperature control, and volumetric displacement control.

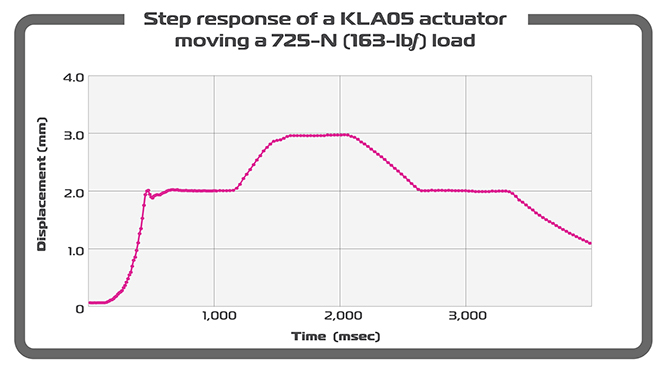

When used for positioning, Kinitics bundled-wire SMA linear actuators output repeatable accuracy and precision to within 5 µm (0.0002 in.). Shown here are the performance characteristics of a KLA05 SMA linear actuator running off 120-Vac input to move 725 N (163 lbƒ) over three positions. By limiting the KCA020 controller gain (as between step one and two shown here) it’s also possible to control the rate of acceleration.

How SMA linear actuators compare to traditional designs

Bundled-wire SMA linear actuators are unique to the linear-motion industry: They don’t use motors or magnetic fields to generate force. Instead, the technology uses shape-memory alloy to generate motion. They’re often less costly than comparably sized electric motors. In addition, SMA linear actuators avoid some of the electrical-noise issues of electromagnetic arrangements and the acoustic noise of mechanical devices such as gearboxes. In fact, bundled-wire SMA linear actuators work without power-transmission components such as gearboxes and ballscrews to translate rotary to linear motion.

| Linear-motion feature | SMA actuators | Solenoids | Electro-mechanical actuators | Voice coils | Pneumatic cylinders | Hydraulic cylinders |

| Position control | Yes | No | Yes | Yes | No | Yes |

| Peak-force hold | Yes | No | No | No | Yes | Yes |

| Direct driving | Yes | Yes | No | Yes | Yes | Yes |

| Bidirectional | No | No | Yes | Yes | Yes | Yes |

| Self-powered | Yes | Yes | Yes | Yes | No | No |

Because they’re a new technology, SMA linear actuators defy the traditional classifications of traditional motion designs.

The best way to summarize the bundled-wire SMA linear actuator is to describe it as a high-force short-stroke option — scalable to about 2,000 N or roughly 500 lb of force. Strokes are to 10 mm or about 0.375 in. Suitable applications are those that need short strokes with exceptionally precise positioning. At MD&M West 2018 in Anaheim, Calif., one demonstration showed a small bundled-wire SMA linear actuator accurately lifting and lowering 160 lb worth of metal weight-training plates with accuracy — to position the weight into within 5 mm.

Such linear motion isn’t possible with most other technology.

Solenoids deliver excellent on-off “bang-bang” strokes — as in poppet valves for fluid-process applications, for example. These valves need a lot of force to act on the spring maintaining pressure during the static state. In contrast, shape-memory alloy linear actuation can serve to make such installations function as proportional valves … because unlike solenoids, controls can drive the actuator to any position to control flow.

Bundled-wire SMA linear actuators can also work as positioners (to compete against piezo technologies) in some cases. Stroke lengths go beyond those of piezos, so design engineers who need more than 0.1 mm — say, to as much as 10 mm — may consider bundled-wire SMA actuation as an option.

Applications here include fine positioning of machining tables, mirror instruments, and other applications that otherwise need the accuracy and precision of piezo actuators but with longer range.

Where stroke lengths are short, SMA actuators even compete against traditional linear-motion actuator setups that pair a rotary electric motor with a rotary-to-linear mechanical device. Elimination of the lost motion, backlash, and wear surfaces of couplings, gearboxes, and other mechanical components makes for higher precision as well as longer life. Potential applications here include those in consumer robotics and electronics, HVAC installations, and medical devices.

Kinitics Automation | www.kiniticsautomation.com

Inspiration behind the new linear-motion design

The direct-drive concept of Kinitics Automation’s bundled-wire SMA technology arose from an automotive application within sister company Biperformance Development Corp. (ShiftFX). In short, ShiftFX wanted to build an optimized clutch control for motorcycles capable of acting as a master cylinder — essentially a piston pump.

“Conventional technologies — in particular, ballscrew-driven actuators — didn’t have enough power density to do the job within the space allotted in the motorcycle footprint,” said Kinitics Automation’s president Dean Pick. “So we stumbled across the shape-memory-alloy technology and began five years of R&D work on adaptations. At that time, nobody had successfully applied it to a linear-motion application.”

Dean Pick in the lab: For quality control and MTBF testing, Kinitics Automation runs a laboratory that includes several wire dynamometers that have logged more than 2 million cycles on single pieces of SMA wire.

In fact, Pick rides motorcycles and served as the test guinea pig for many of Kinitics Automation’s early uses of the shape-memory-alloy products. Once perfected, the team at Kinitics realized the technology might be useful for other linear applications in other industries. So now, it’s established an entire family of SMA linear actuators and piston pumps.

Filed Under: Linear Motion Tips, Gears • gearheads • speed reducers

Tell Us What You Think!