When just 100th of a second determines a winner, car racing team owners

and members constantly seek ways to shave time from every aspect of a

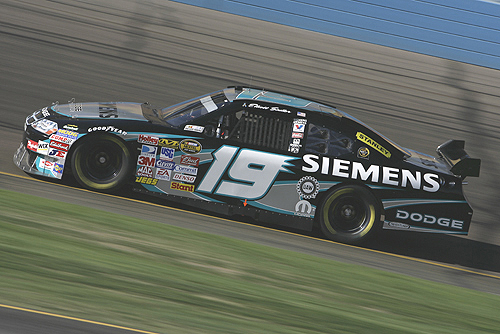

race. Gillett Evernham Motorsports (GEM) in Statesville, N.C. knows

that the performance of a tire handler behind the pit wall can be as

important to winning as the right driver. For its three teams that

compete in NASCAR’s Sprint Cup Series and one team in the NASCAR

Nationwide Series, consistent execution and continuous improvement are

a way of life.

NASCAR

pit crews once relied on VHS video or DVDs to record, replay and

evaluate pit stops. Unfortunately, the videos seldom recorded the

important work of handling air hoses and tires behind the wall. It also

took precious minutes to cue the videos up for replay following a pit

stop. Indexing from one part of the video to the next was tedious and

difficult. GEM eliminated these problems by using a sophisticated touch

screen computer technology from Siemens Energy & Automation.

Siemens’ compact, 19.1” SIMATIC® Panel PC touch screen color displays

are mounted on each GEM team’s pit cart located just outside the wall

of the pit box.

Enclosed in durable metal housings, these

panel PCs are built to withstand the intense vibration produced when

800 HP cars pit within feet of the cart numerous times during a race.

They also hold up under the stress of being shipped to race tracks for

38 races in the United States, Mexico and Canada where they operate in

hot, cold, rain, snow and sleet–and boot up every time.

Timing the crew to a 1/1000th of a second while eliminating tedious editing.

By

using the very accurate playback capabilities of the Siemens touch

screen panel PCs combined with the DB software, GEM can now time the

crew to 1000th of a second. Also, with a very high memory capacity and

a resolution of 1280 X 1024 pixels, the crew can easily see how they

perform on the full screen.

Every part of each pit stop is

scrutinized immediately following a stop. Each corner of the pit box

and the activity behind the wall are captured by two video cameras

mounted on the pit cart. The video is converted to a digital signal

then sent via FireWire to the touch screen panel PC. The pit stop may

be immediately replayed simply by touching the screen. An indexing

device simplifies rewinding, zooming, fast-forwarding, pausing and slow

motion.

Eric Wilson, jackman for the No. 9 car driven by popular

driver Kasey Kahne and GEM pit crew coordinator, says the Siemens touch

screen panel PC technology allows him to identify mistakes and correct

potentially dangerous problems.

“One racetrack has small pit boxes

with painted white lines,” Wilson says. “In our first two stops, our

crew members were slipping on these lines. By using the touch screen,

we were able to zoom in and determined the problem was caused by a

little bit of brake dust sitting on top of the line.”

Moreover,

the touch screen panel PCs and software have reduced the editing time

from a day to just a few minutes. Whereas the video once had to be

converted to a digital signal requiring a tedious process of hitting

stop, play and fast forward while looking at a stopwatch, it takes just

a few minutes to break down the film while flying back from a race.

Even with a great car, you don’t win races without a great pit crew.

Today,

the average GEM pit stop time is respectable 12.6 seconds. By next year

the goal is to lower pit stops to the high 11s or low 12s. In sum,

NASCAR visionary Evernham says GEM is partnering with technology

partners like Siemens to beat every body at every pit stop.

“Siemens

has been a great partner in many ways,” says Ray Evernham. “The

technology and knowledge they have provided to our team has allowed us

to work on and develop some new strategies to be our best on every race

day.”

::Design World::

Filed Under: Automotive, ENGINEERING SOFTWARE, Displays • HMIs • operator interfaces • monitors

Tell Us What You Think!