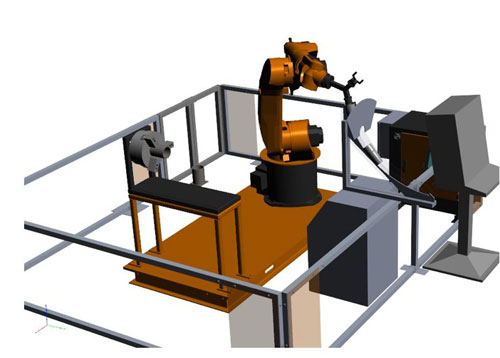

At this year’s International Manufacturing Technology Show (IMTS) in Chicago, Siemens will demonstrate its recent collaboration with KUKA Robotics. In the Siemens booth E-5010, a KUKA robot will be articulating parts, simulating the operation on a CNC machine tool. Key to this development is the machine builder’s ability to integrate mxAutomation from KUKA directly through the Siemens Sinumerik CNC platform, thereby allowing the operator of the machine to run both the machine tool and robot from the single control panel. .

The motion sequence of the robot is entirely engineered within the Sinumerik 840D sl CNC, then transferred by the 840D sl’s PLC function to the mxAutomation interpreter on the KR C4. All program changes to a six-axis robot can easily be input on a second channel of the CNC and fully operated. This scenario provides the ability to not only run a machine tool’s automation sequence more efficiently, but also make more changes on-the-fly to minimize machine downtime, with no special knowledge of robot programming language. During the operation of the machine tool, all changes made can be visualized directly on the CNC screen, further minimizing operator actions.

During the show, a Siemens Sinumerik 840D sl CNC will be programmed to allow the operator to jog the robot, command the gripper and otherwise simulate integrated actions with a machine tool.

In operation, the KRC4 integrator and mxAutomation convert the robot language into the same commands used for multi-axis machine tool functions. A single Profinet cable runs between the robot and the CNC.

All safety functions and test functions for load / unload, brake test, gripper, robot communication and safe operation of the robot are provided through the Siemens Profinet and Profisafe platforms.

Siemens

www.usa.siemens.com

Filed Under: Factory automation, The Robot Report, Mechatronics

Tell Us What You Think!