Researchers at the Georgia Tech Research Institute (GTRI) are developing a solid composite material to help cool small, powerful microelectronics used in defense systems. The material, composed of silver and diamond, promises an exceptional degree of thermal conductivity compared to materials currently used for this application.

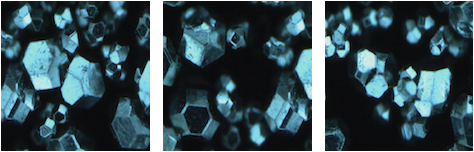

These microscope images show diamond particles suspended in the composite material. (photo by Jason Nadler)

The research is focused on producing a silver-diamond thermal shim of 250 μ or less. The ratio of silver to diamond can be tailored to allow the shim to be bonded with low thermal expansion stress to the high power wide-bandgap semiconductors planned for next generation phased-array radars.

Thermal shims pull heat from these high power semiconductors and transfer it to heat dissipating devices such as fins, fans or heat pipes. Since the semiconductors work in confined operating spaces, it is necessary that the shims be made from a material that packs high thermal conductivity into a tiny structure.

Diamonds provide the bulk of thermal conductivity, while silver suspends the diamond particles within the composite and contributes to high thermal conductivity that is 25% better than copper. To date, tests indicate that the silver-diamond composite performs extremely well in two key areas — thermal conductivity and thermal expansion.

“We have already observed clear performance benefits – an estimated temperature decrease from 285° C to 181° C – using a material of 50% diamond in a 250-μ shim,” said Jason Nadler, a GTRI research engineer who is leading the project.

The researchers are approaching diamond percentages that can be as high as 85% in a shim less than 250 μ in thickness. These increased percentages yield even better performance results in testing.

Nadler added that this novel approach to silver-diamond composites holds definite technology transfer promise. No material currently available offers this combination of performance and thinness.

GTRI researcher Jason Nadler holds a sample of thin silver-diamond composite material. (photo by Gary Meek)

Diamond is the most thermally conductive natural material, with a rating of approximately 2,000 W/mK, which is a measure of thermal efficiency. Silver, which is among the most thermally conductive metals, has a significantly lower rating — 400 W/mK.

Diamond has a very low coefficient of thermal expansion of about two parts per million/Kelvin (ppm/K). But the materials used to make wide-bandgap semiconductors — such as silicon carbide or gallium nitride – have higher CTEs, generally in the range of 3 to 5 ppm/K.

By adding in just the right percentage of silver, which has a CTE of about 20 ppm/K, the GTRI team can tailor the silver-diamond composite to expand at the same rate as the semiconductor material. By matching thermal expansion rates during heating and cooling, the researchers have enabled the two materials to maintain a strong bond.

Diamond conducts heat by means of phonons, which are vibrational wave packets that travel through crystalline and other materials. Introducing silver between the diamond-particle interfaces helps phonons move from particle to particle and supports thermal efficiency.

Georgia Institute of Technology

www.gatech.edu

::Design World::

Filed Under: Aerospace + defense, Semiconductor manufacture, Materials • advanced, Energy management + harvesting

Tell Us What You Think!